The Argweld PurgEye family includes a range of auxiliary products designed to enhance the functionality and performance of your Weld Purge Monitors. These innovative tools, including the PurgeNet Dew Point Purging Gas Moisture Sensor, Smart Cable, PurgeAlarm Visual Alarm Indicator, PurgeLog Data Logging Software, and Automatic Machine Interface Lead, ensure precise control and monitoring of oxygen levels and environmental conditions during critical welding processes.

The Argweld PurgEye family includes a range of auxiliary products designed to enhance the functionality and performance of your Weld Purge Monitors. These innovative tools, including the PurgeNet Dew Point Purging Gas Moisture Sensor, Smart Cable, PurgeAlarm Visual Alarm Indicator, PurgeLog Data Logging Software, and Automatic Machine Interface Lead, ensure precise control and monitoring of oxygen levels and environmental conditions during critical welding processes.

The PurgeNet Dew Point Purging Gas Moisture Sensor simplifies measuring moisture levels in purging gas for critical welds. It integrates seamlessly with any 1 ppm PurgEye Weld Purge Monitor, eliminating the need for a separate dew point meter and ensuring accurate monitoring of dew point moisture levels.

The PurgeNet Smart Cable connects with the Argweld PurgEye Weld Purge Monitors and all innovative accessories for weld purging. It can link to the PurgeAlarm Traffic Light System for visual warnings and charge your monitor. Additionally, it works with PurgeLog software to transfer purge data to a PC for quality control.

Available in a kit form, all suitable sizes for Orbital Welding in particular. Each kit is supplied in a strong sturdy carrying case for ease of storage and to maintain and keep the Orbital Welding Purge Plugs clean suitable for cleanrooms and the like.

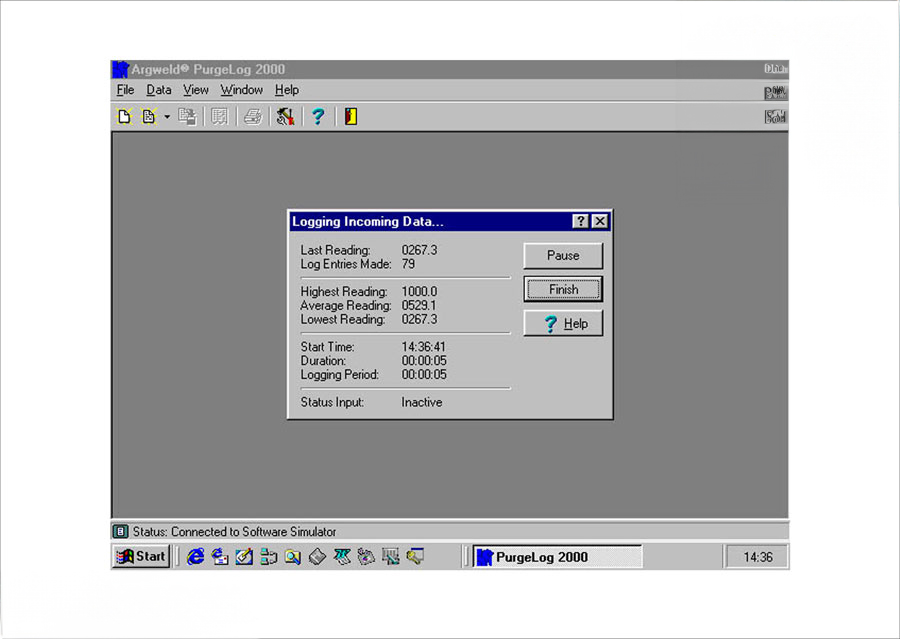

PurgeLog software, included with all high-spec PurgEye Weld Purge Monitors measuring down to 1 ppm, allows easy data transfer for quality control documentation and weld certifications. It is provided on a USB stick for easy installation on Windows-based PCs and enables data transfer via PurgeNet.

The PurgeNet Automatic Machine Interface Lead enables control of PPM readings with welding power sources. It communicates oxygen readings from your PurgEye Weld Purge Monitor to other equipment. It automatically pauses the welding process if the oxygen content falls below a set level, ensuring optimal welding conditions.