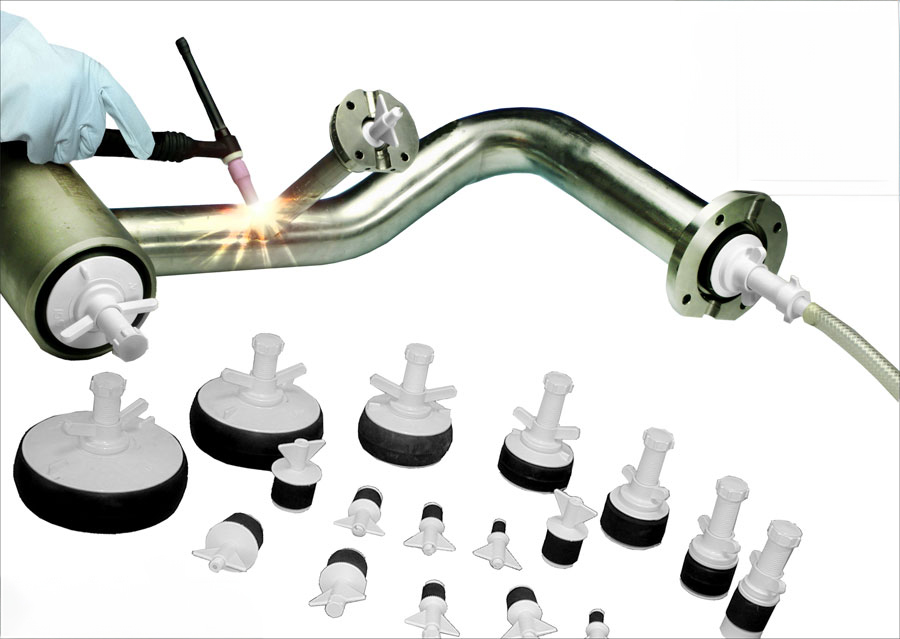

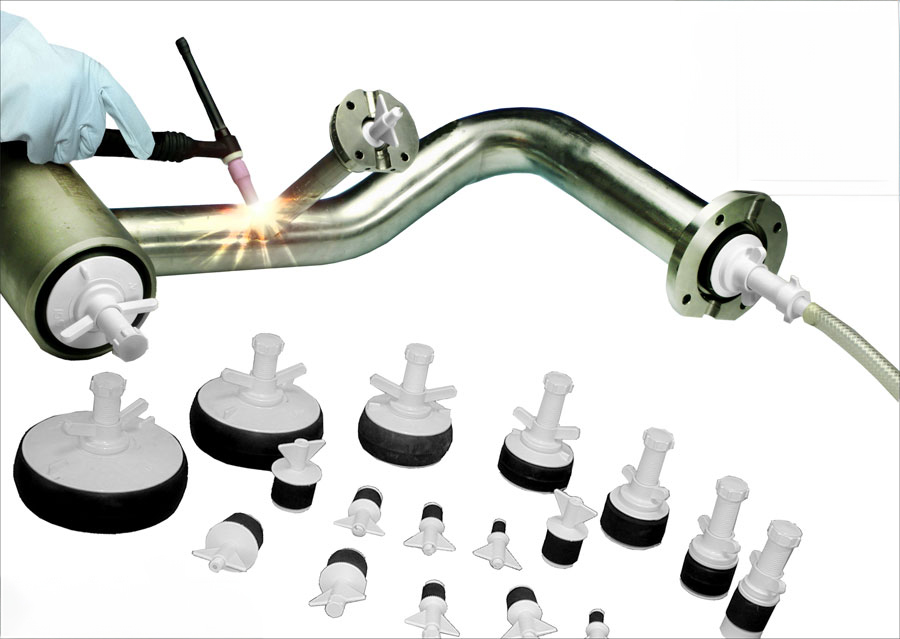

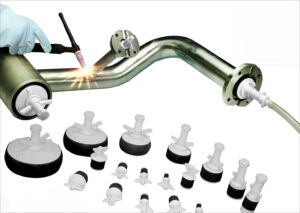

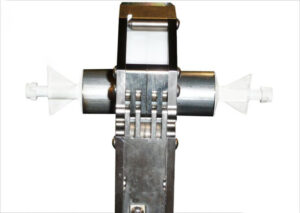

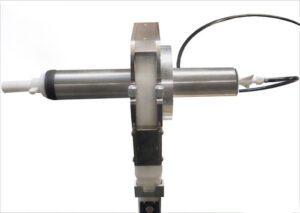

where inflatable purging systems, paper dams, or water-soluble films may not be available or practical.

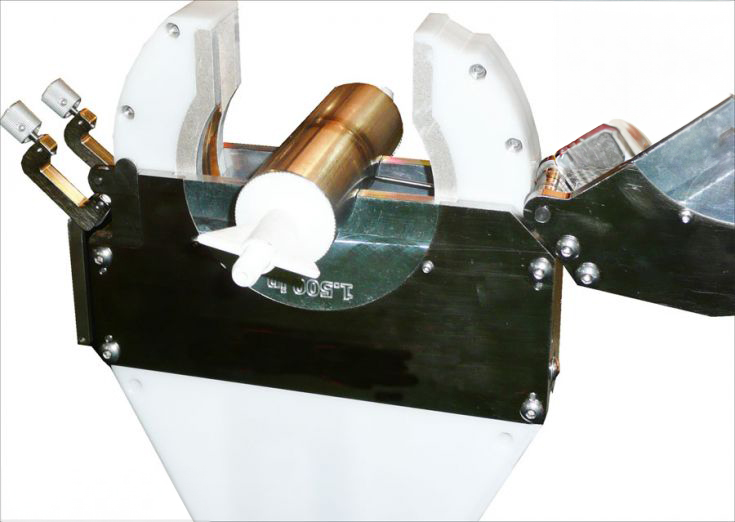

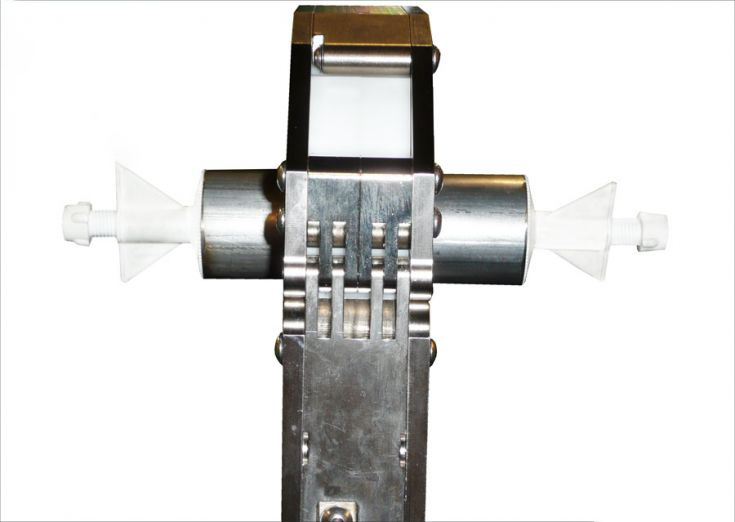

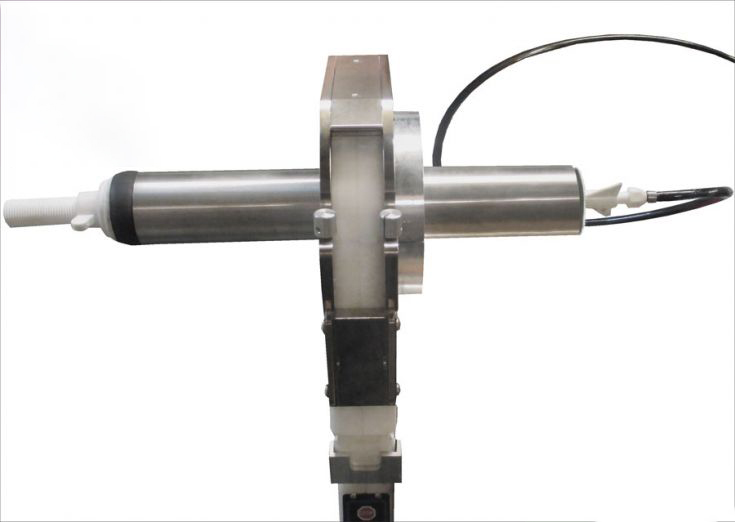

This is suitable for short, complicated, variable-size assemblies where purging systems or dams would be too long or do not match the diameters being worked on.

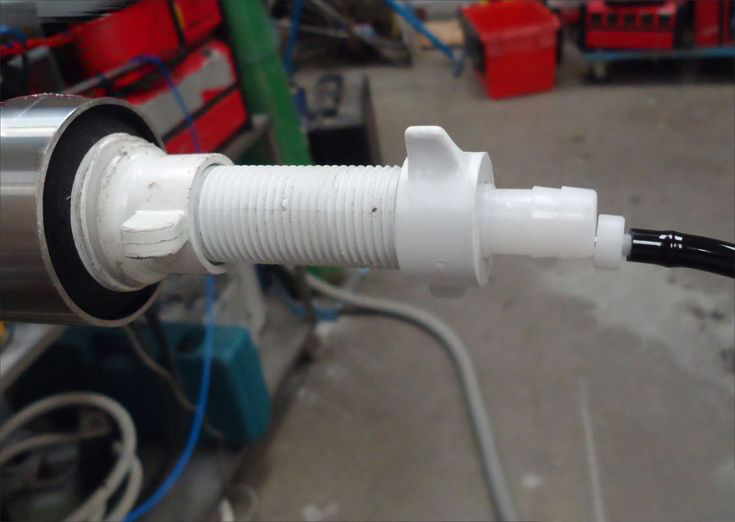

These plugs are also ideal for creating an airtight seal for leak testing operations.

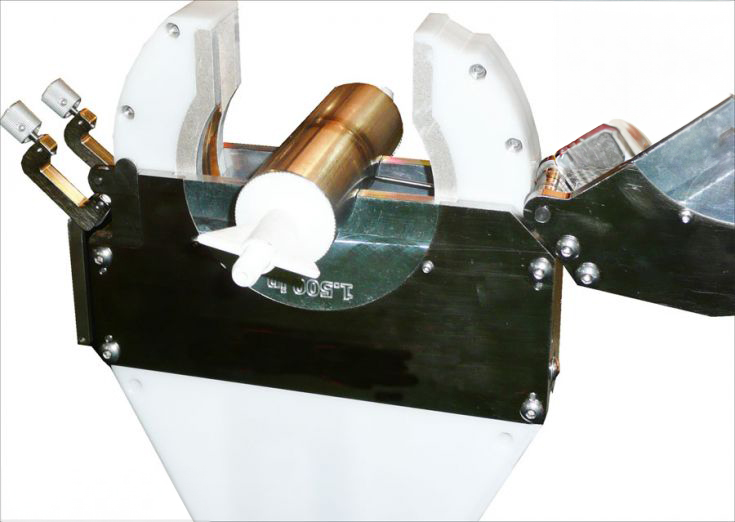

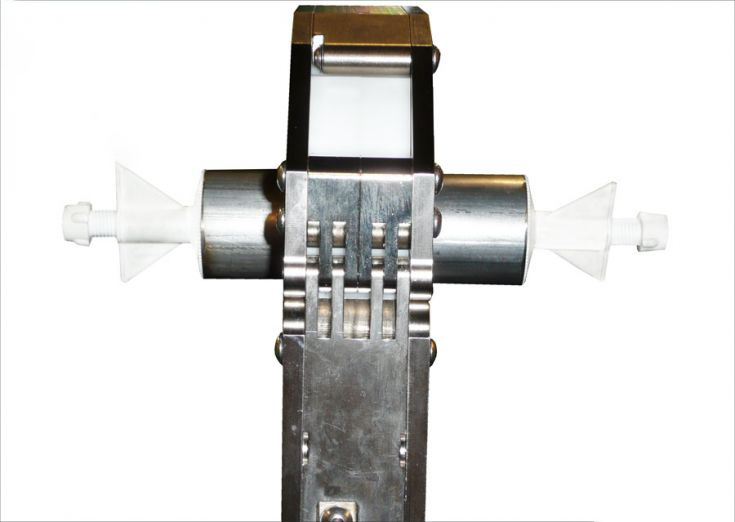

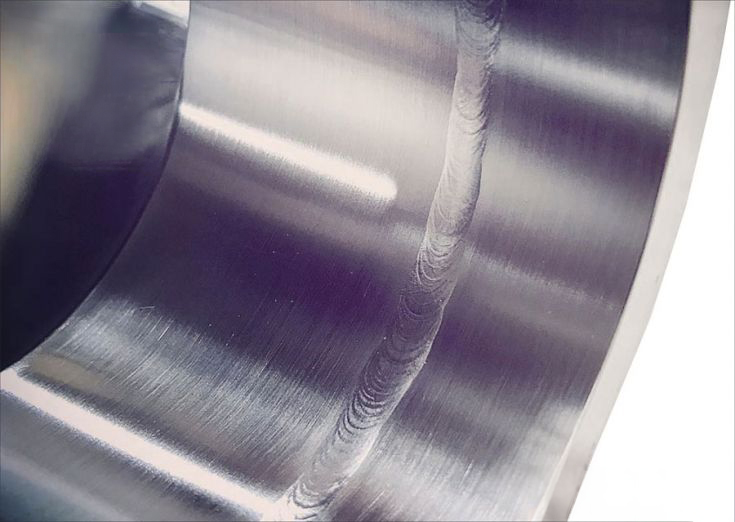

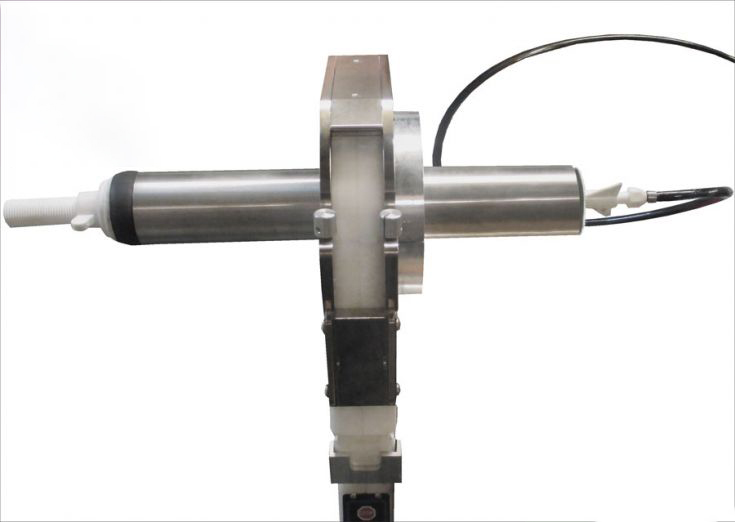

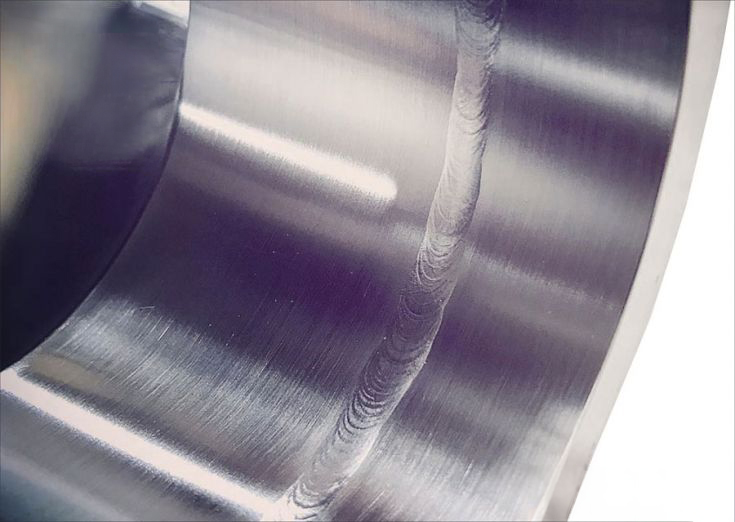

For welding of alloys and stainless-steel tubes and pipes, Argweld® Purge Plugs™ are available as single units or as kits for typical applications, such as Orbital Welding. When filling complicated pipework systems with inert gas, the Argweld® Purge Plugs™ are perfect for sealing all holes and orifices for quality internal purging.

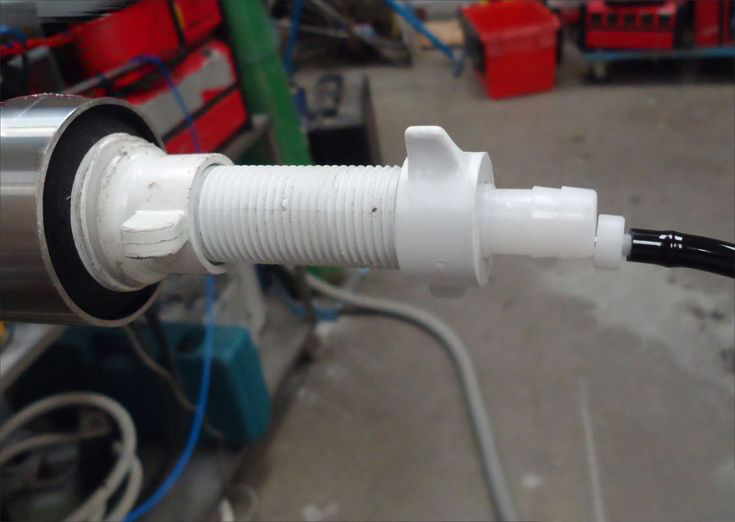

These are made from high-quality nylon up to 152 mm (6") diameter, ensuring they will not rust, corrode, seize, or lock. They are virtually shatter-proof and easily dismantled for cleaning.

A friction-reducing acetal copolymer thrust washer between the top plate and wing nut provides easy expansion and release.

Larger size plugs incorporate strengthening ribs in the top and bottom plate design.

Standard seals are made from natural rubber, with silicone and nitrile rubber alternatives available.

All plugs conform to British Standards BS 8005 for low-pressure testing and sealing of pipes.

The kit contains the most common sizes of Argweld® Purge Plugs™ used, packaged in a robust ABS plastic case with custom-cut foam inlays for easy storage and quick access.

Argweld® Weld Purging Plugs™ are a versatile and essential tool for effective pipe purging, ensuring high-quality, defect-free welds in various industrial applications.

Plugs are available individually or in kits for immediate delivery.

"The purge meters are second to none."

"I am a huge fan of Huntingdon products and have talked to others over the years about using them. The purge meters are second to none. I own and use regularly my PurgEye 100 and my PurgEye 300. I think somewhere, I still have my original Argweld® MKV monitor, which sadly no longer powers up. I am a scarce breed because I have 3 degrees and a complete academic understanding of metallurgy, but more importantly, welding science; I also have over 20 years of hands-on experience in welding on drill floors, firing lines, and vessel shops. I quite literally have a passion for old-fashioned welding! Excellent product, guys!"

Davina Urquhart

CITY COLLEGE AND SENIOR WELDING ENGINEER AT TRANSWELD SERVICES LTD

"One of the best, if not the best, residual oxygen detector instruments on the market."

"I believe the PurgEye to be one of the best if not the best, residual oxygen detector instruments on the market with its digital residual oxygen level LED display readouts measuring as low as 0.01% and its large, user-friendly viewing screen making it easier for me to read. I also believe the PurgEye has great accuracy in residual oxygen, with speedy measurements displayed within seconds. The PurgEye is a far cry from the old school homemade 'use a cigarette lighter' to check purge gas flow system."

Construction and Maintenance

PIPING SOLUTIONS PTY LTD, AUSTRALIA

"Purge monitors are a necessity."

"I can personally vouch for purge monitors. When working with medium to large-diameter exotic pipework, they can prevent you from having a terrible day! I've only used the older model, which was a godsend. Anyone, from the welder who has had to carry out weld repairs due to root weld oxidation (or coking) on such materials, to the directors facing an expensive bill for re-work and possible tarnished company reputation, to the client with their project now running behind schedule - knows exactly what I mean. Purge monitors are a necessity."

Colin Sherriffs

WELDING AND FABRICATION INSTRUCTOR/ASSESSOR AT ITCA LTD