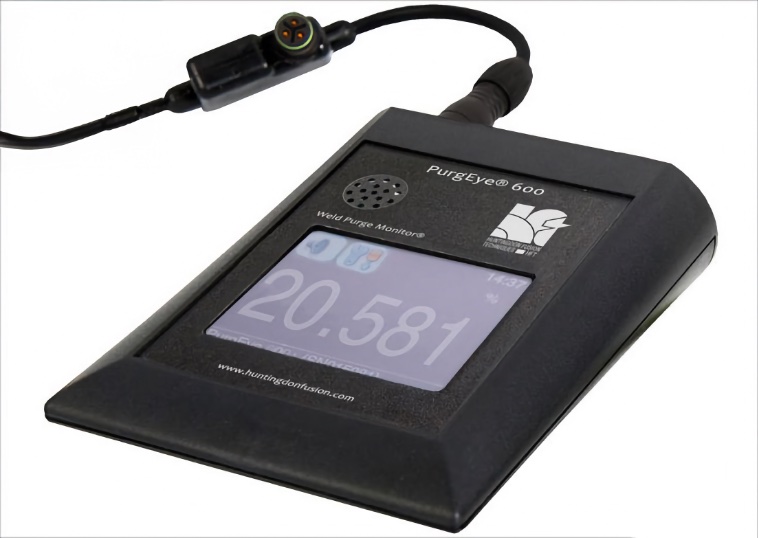

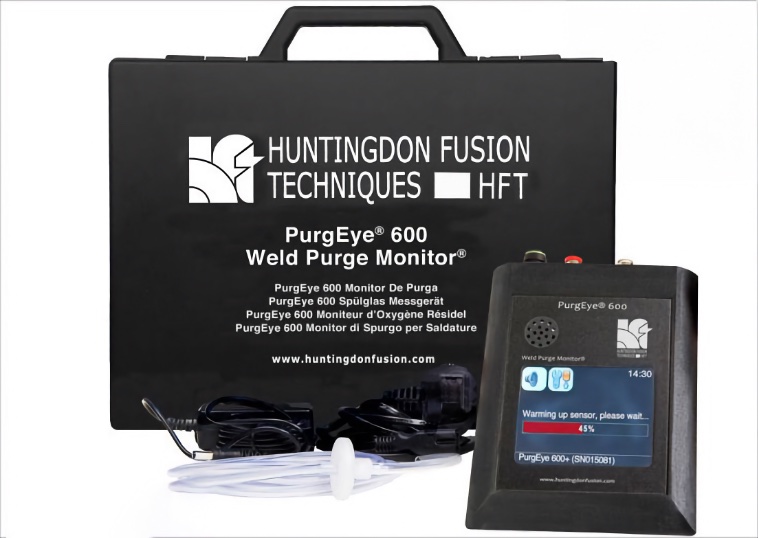

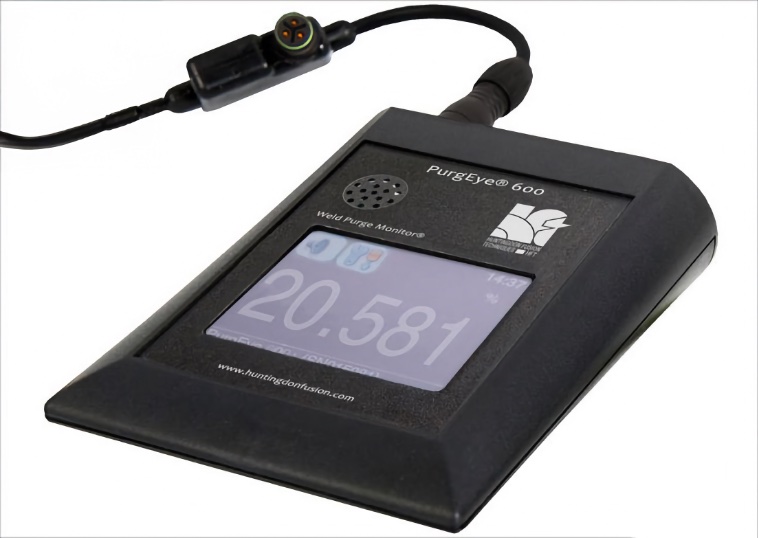

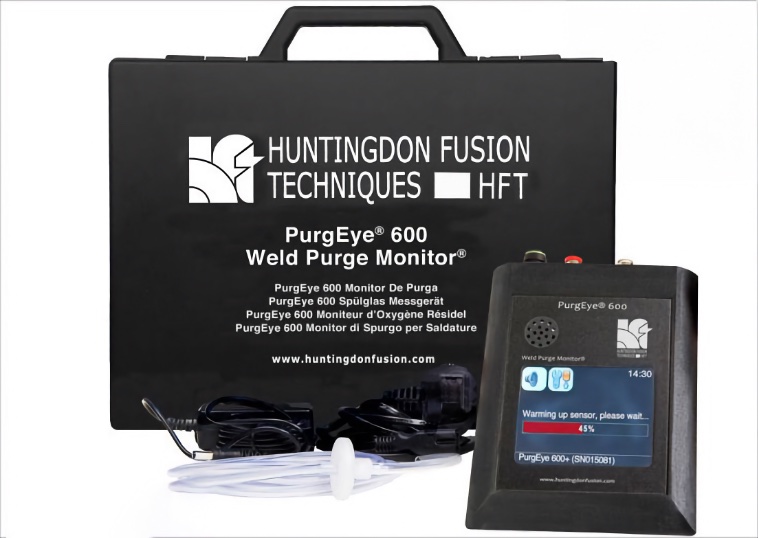

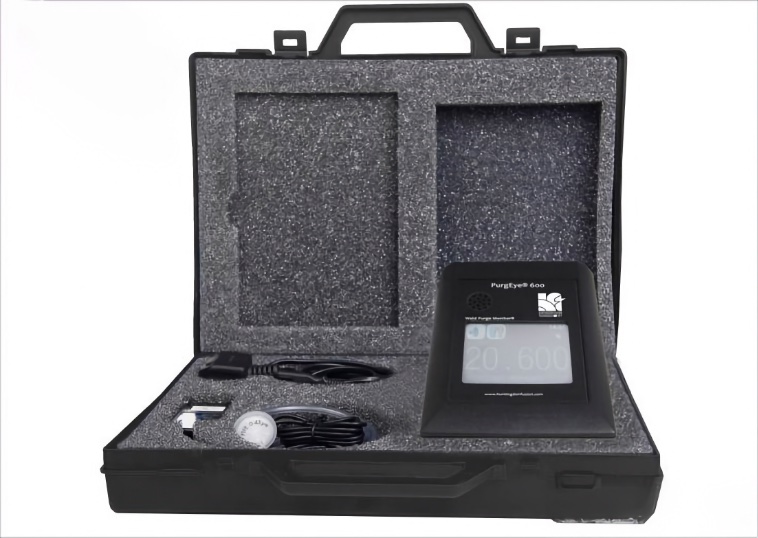

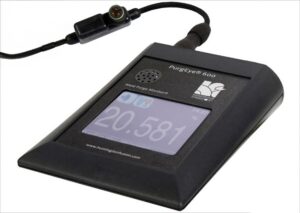

This system provides highly accurate oxygen level measurements from 20.94% down to 1 ppm, ensuring the best weld quality.

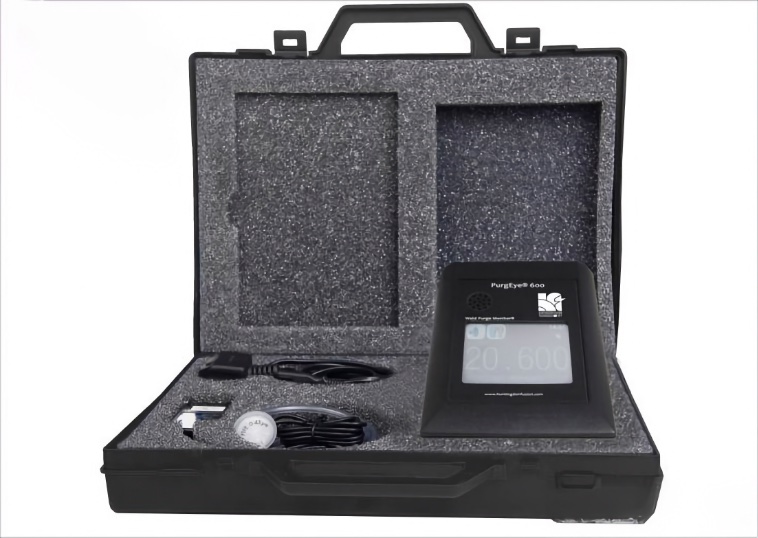

PurgeNet™ and PurgeLog™ enable seamless control of welding processes and comprehensive data logging for Quality Management.

The colour touch screen and intuitive interface make it easy to operate and customise for specific welding needs.

HFT®’s Dew Point Sensor can be connected to the PurgEye® 600 via PurgeNet™ for accurate dew point measurement, which is essential for maintaining weld integrity. This sensor is compatible with all PurgEye® monitors reading down to 1 ppm, including:

The PurgEye® monitors measure oxygen levels within any gas, not just inert gases. They can be used with argon, helium, nitrogen, and nitrogen/hydrogen mixes.

"The purge meters are second to none."

"I am a huge fan of Huntingdon products and have talked to others over the years about using them. The purge meters are second to none. I own and use regularly my PurgEye 100 and my PurgEye 300. I think somewhere, I still have my original Argweld® MKV monitor, which sadly no longer powers up. I am a scarce breed because I have 3 degrees and a complete academic understanding of metallurgy, but more importantly, welding science; I also have over 20 years of hands-on experience in welding on drill floors, firing lines, and vessel shops. I quite literally have a passion for old-fashioned welding! Excellent product, guys!"

Davina Urquhart

CITY COLLEGE AND SENIOR WELDING ENGINEER AT TRANSWELD SERVICES LTD

"One of the best, if not the best, residual oxygen detector instruments on the market."

"I believe the PurgEye to be one of the best if not the best, residual oxygen detector instruments on the market with its digital residual oxygen level LED display readouts measuring as low as 0.01% and its large, user-friendly viewing screen making it easier for me to read. I also believe the PurgEye has great accuracy in residual oxygen, with speedy measurements displayed within seconds. The PurgEye is a far cry from the old school homemade 'use a cigarette lighter' to check purge gas flow system."

Construction and Maintenance

PIPING SOLUTIONS PTY LTD, AUSTRALIA

"Purge monitors are a necessity."

"I can personally vouch for purge monitors. When working with medium to large-diameter exotic pipework, they can prevent you from having a terrible day! I've only used the older model, which was a godsend. Anyone, from the welder who has had to carry out weld repairs due to root weld oxidation (or coking) on such materials, to the directors facing an expensive bill for re-work and possible tarnished company reputation, to the client with their project now running behind schedule - knows exactly what I mean. Purge monitors are a necessity."

Colin Sherriffs

WELDING AND FABRICATION INSTRUCTOR/ASSESSOR AT ITCA LTD