Overview of Arc Welding Processes

Arc welding is a group of techniques used to join metals by generating intense heat through an electric arc between an electrode and the metal workpieces. Among the many arc welding processes available, four are predominantly used due to their effectiveness and control: Gas Tungsten Arc Welding (GTAW/TIG), Gas Metal Arc Welding (GMAW/MIG/MAG), Plasma Arc Welding (PAW), and Submerged Arc Welding (SAW). These processes have evolved significantly since their inception in the late 19th century, becoming essential, especially in industries like shipbuilding during World War II.

What is an Electric Arc?

An electric arc is a sustained energy discharge between two conductors at different voltages. In welding, this arc is created by momentarily bringing the conductors (the electrode and the metals to be welded) together to form a short circuit and then pulling them apart. The arc can only be maintained over a small gap, requiring skilled operation. Advances in technology have led to sophisticated power supplies that stabilise the arc, enhancing the quality and consistency of welds.

The temperature in an electric arc can range from 5,000ºC to 20,000ºC, making it sufficient to melt and fuse a wide range of metals, including those with melting points up to 1,500ºC.

Key Arc Welding Processes

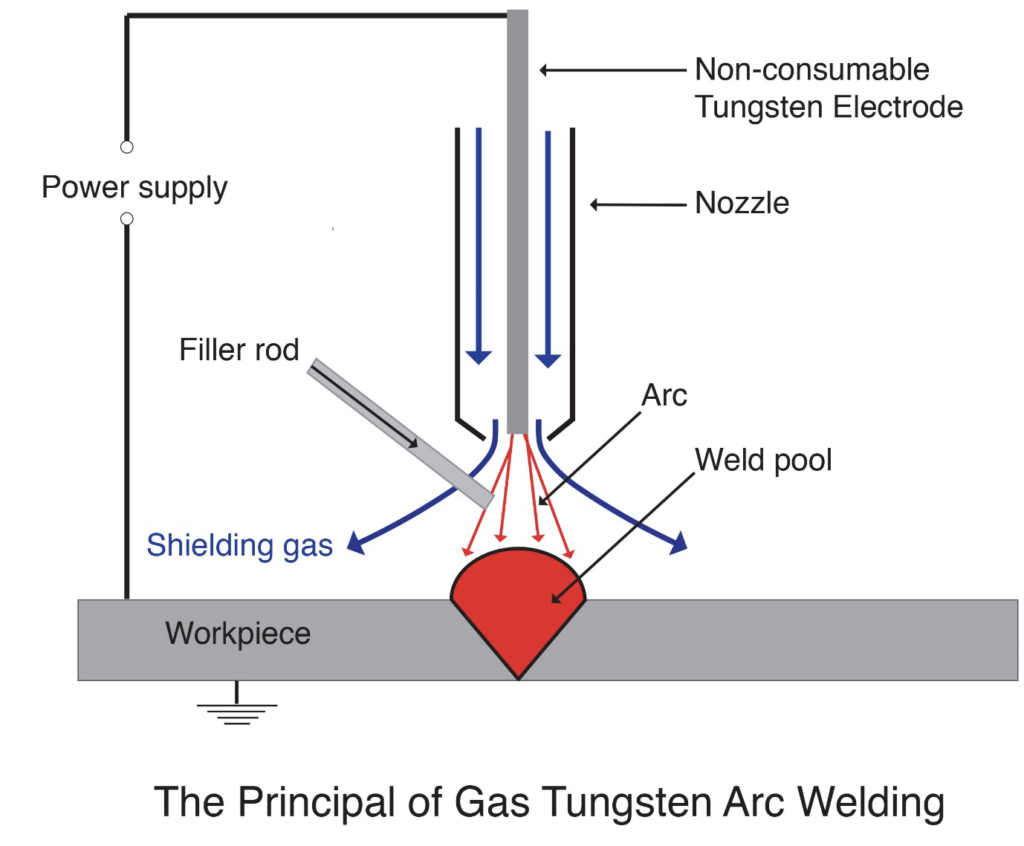

Gas Tungsten Arc Welding (GTAW/TIG)

GTAW, or TIG welding, uses a non-consumable tungsten electrode to create the arc. An inert gas, typically argon, shields the electrode and the weld area from atmospheric contamination, particularly oxidation. Filler metal may be added either manually or mechanically.

Advantages

Disadvantages

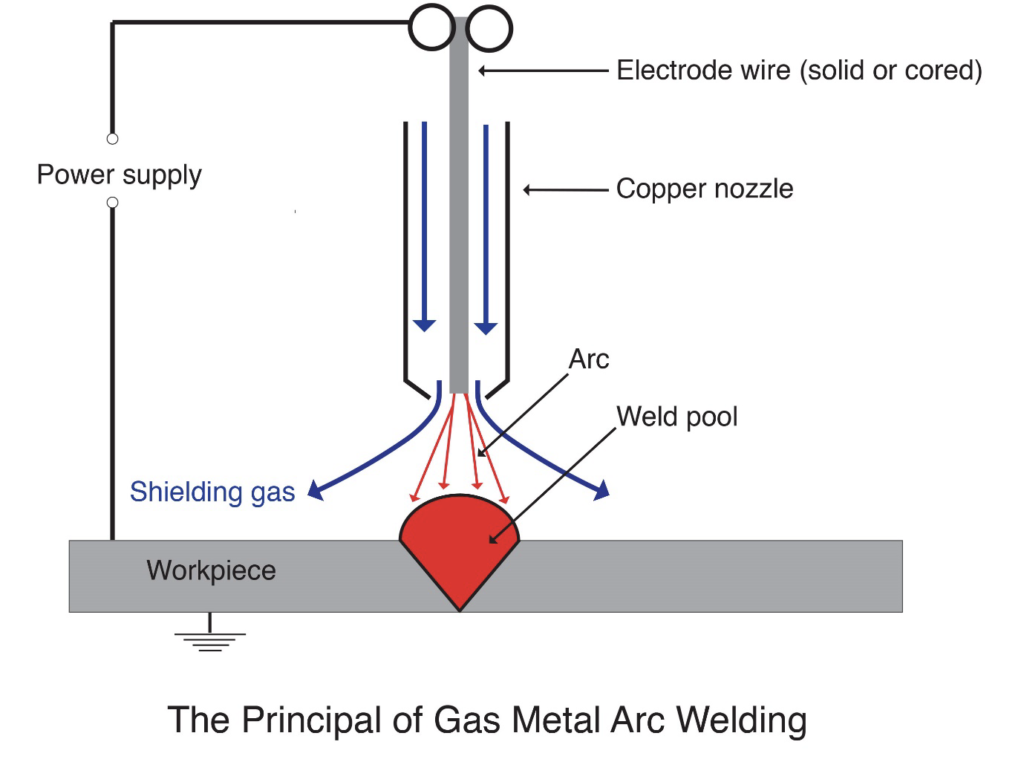

Gas Metal Arc Welding (GMAW/MIG/MAG)

GMAW involves creating an arc between a continuously fed wire electrode and the workpiece. An inert gas like argon, or a mix of inert and active gases, shields the weld from contamination.

Advantages

Disadvantages

Plasma Arc Welding (PAW)

PAW shares similarities with GTAW and GMAW but uses a constricted arc between a tungsten electrode and a water-cooled nozzle or the workpiece itself. The filler metal is added separately.

Advantages

Disadvantages

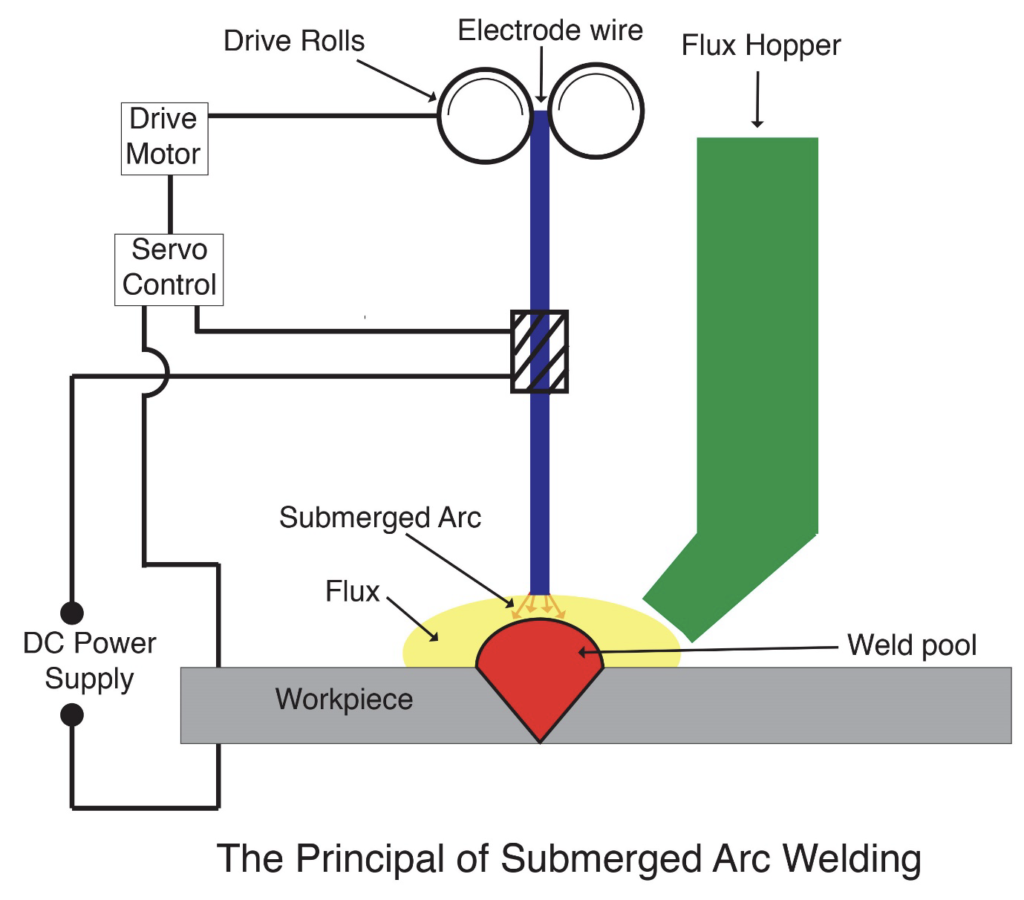

Submerged Arc Welding (SAW)

SAW uses a granular flux to shield the weld area instead of inert gas. The arc is hidden beneath this flux, which melts to protect the weld pool, solidifies as the weld cools, and is continually replaced as welding progresses.

Advantages

Disadvantages

Welding Hazards

Welding Fume

Welding fumes contain hazardous substances from metals, coatings, and gases. Local exhaust ventilation systems and respiratory protective equipment (RPE) can mitigate these.

Tungsten Toxicity

While pure tungsten has a high melting point, additives like thoria, though enhancing performance, carry toxicity risks, safer alternatives to thoriated tungsten are available and recommended.

Inert Gas Hazards

While non-toxic, inert gases like argon are heavier than air and can cause asphyxiation in confined spaces. Adequate ventilation and careful handling are crucial.

Arc Eye

Exposure to ultraviolet radiation from the welding arc can cause "arc eye," a painful condition. Protective eyewear with special glass filters is essential to prevent this.

Intense Heat

The extreme heat generated during welding can cause burns and other injuries. Proper protective gear, including gloves and face shields, is vital for safety.

References

This guide provides a foundation for understanding the principal arc welding processes and their respective advantages and disadvantages. Additionally, awareness of the associated hazards ensures that safety remains a priority in all welding activities.