Weld Purging Technology. The welding of certain metals such as nickel alloys can be challenging.

A company in Australia who needed some help welding copper nickel pipe recently approached Huntingdon Fusion Techniques HFT®. They were having trouble eliminating impurities in the root of the weld inside the pipe and asked if Huntingdon Fusion Techniques HFT® could help with their expertise in the field of Weld Purging Technology.

Ron Sewell, Chairman for HFT® said: “After a question and answer session and gaining a little more information, I was able to use my own personal experience to give some advice.”

Here are some tips:

Cleaning:

- Copper nickel has a tenacious oxide film on the outside and that must be removed. This can be done by belt or disc sanding.

- The material must then be thoroughly degreased with a suitable solvent.

- Stainless steel wire brushes and stainless steel wool are good materials to use for cleaning as well.

- This cleaning equipment must not be used on any other material, so as to avoid cross contamination.

- Copper nickel fabrication should also be separated from any other manufacturing areas to avoid contaminating dust settling on the materials or cleaning equipment.

- If air powered tools are used for cleaning or grinding, they can leave an oil film on the materials because compressed air is never completely free of oil.

- If not completely removed or cleaned it can result in porosity.

Weld Purging:

- If the argon internal purging process contains even the tiniest amounts of oxygen, carbon dioxide or nitrogen, porosity will result.

- A very good pipe purge system must be used with an accurate Pipe “Weld Purge Monitor®” that can measure oxygen levels down to 10 ppm.

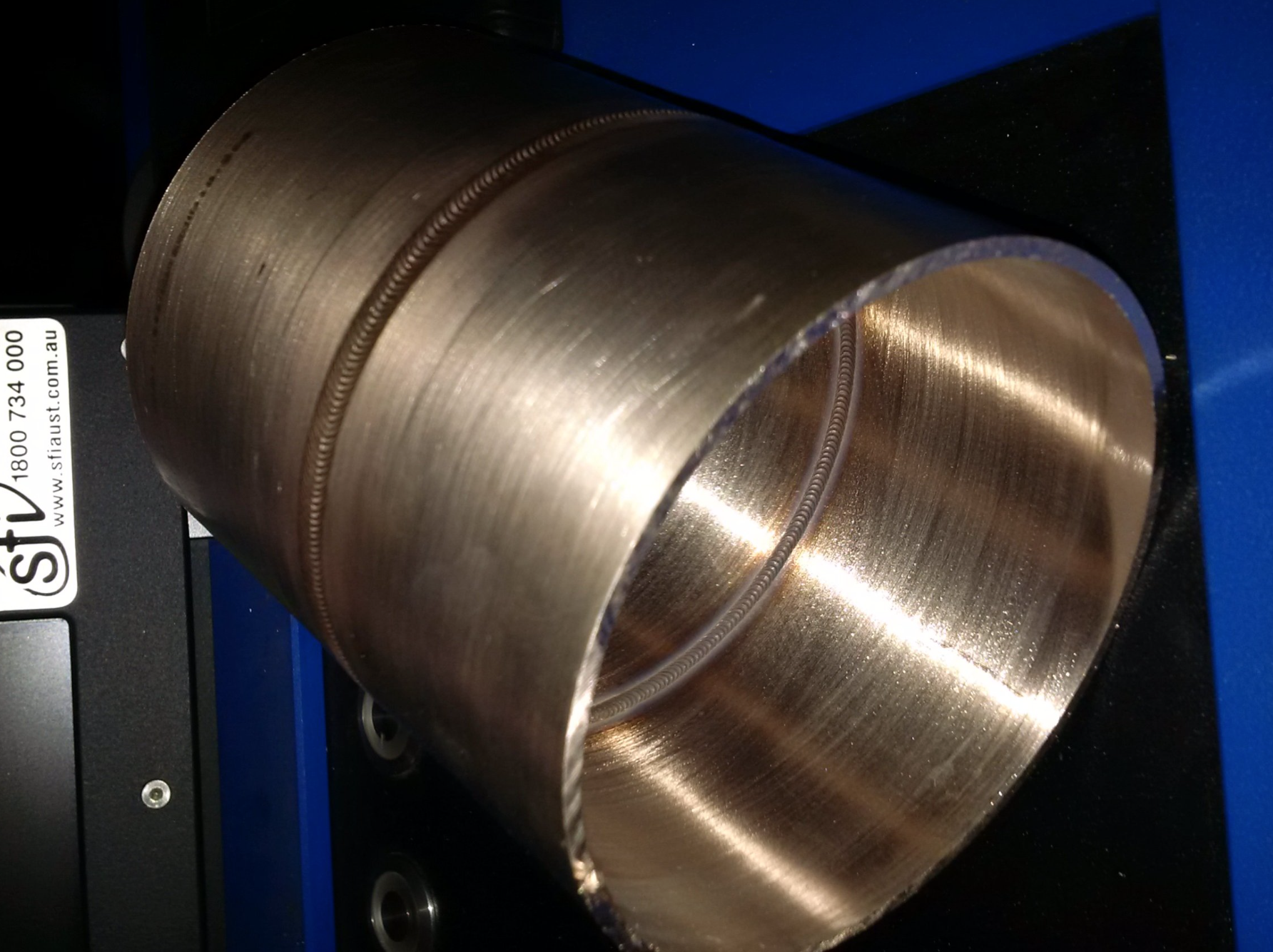

The finished result of the welded copper nickel pipe.

In addition to these helpful tips, our White Paper – 205 Help with Nickel Alloy Welding is available on our website.

Huntingdon Fusion Techniques HFT® are renowned for our Worldwide support. If you have any Weld Purging issues that you need help and advice with, then get in touch!