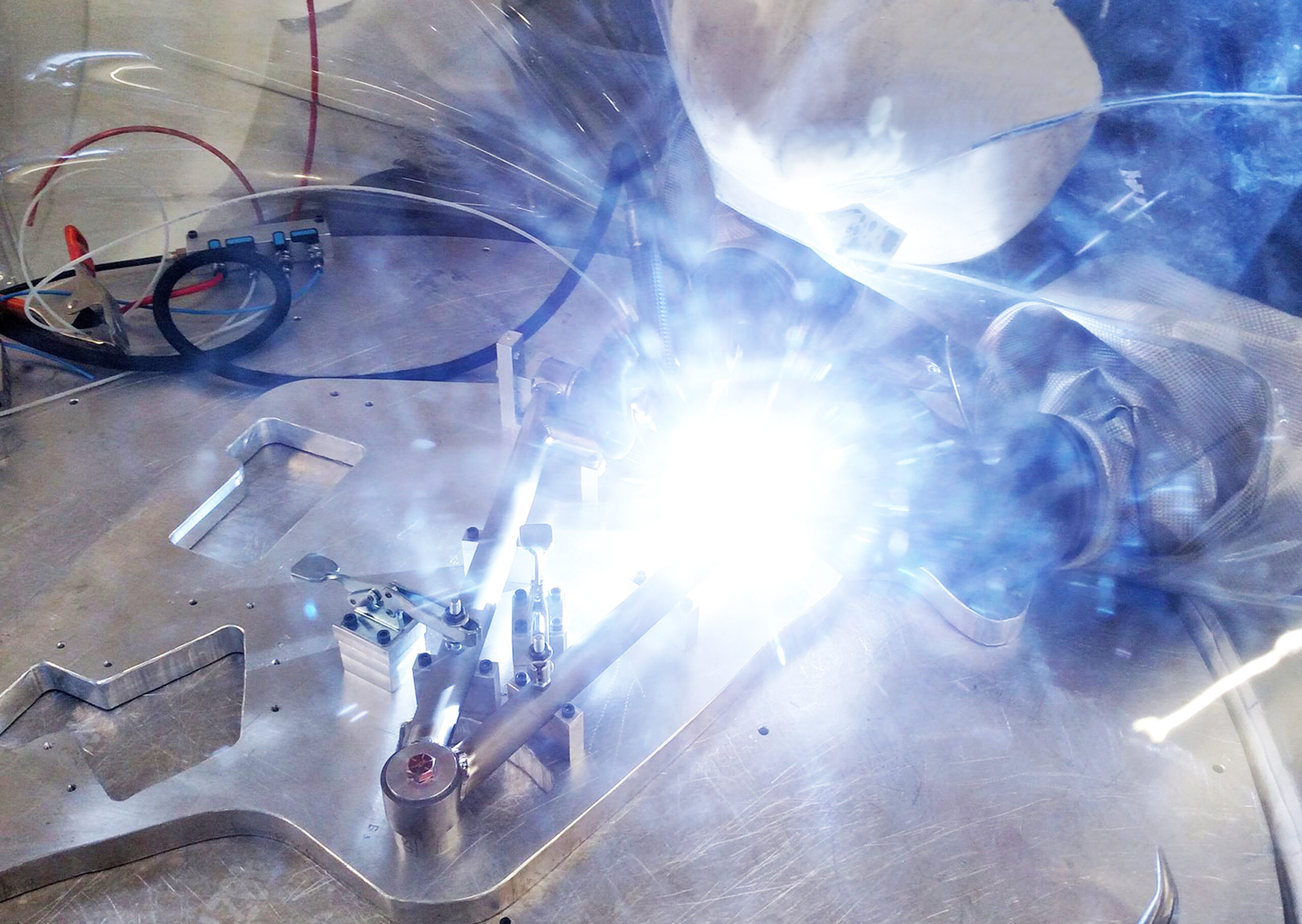

Weld Purge Chambers are in use Worldwide to obtain zero colour titanium and special stainless steel welds. At Huntingdon Fusion Techniques HFT®, we manufacture a range of standard and non-standard chambers. Notable names in the aerospace, sports vehicle and medical industries have purchased our enclosures. More recently the chambers have been manufactured for titanium bicycle manufactures and for wire plus arc additive manufacturing (WAAM).

Two sets of glove ports are manufactured as standard on each chamber. The upper section of each enclosure is optically clear, providing excellent welding vision. An entry lock makes it possible to take parts in or out of the chamber without affecting purge quality.

These Flexible Welding Enclosures ® are a highly effective device for welding with oxygen levels down to 10 parts per million (ppm). They are manufactured from UV-resistant polyvinyl chloride (PVC).

A purge gas entry port and an exhaust valve are included on each enclosure to vent displaced gas into the atmosphere. There is a special outlet for a Weld Purge Monitor ®, next to the exhaust to monitor the oxygen level inside the chamber before, during and after welding.

Standard Weld Purge Chambers are available off the shelf in diameters of 900, 1,200, 1,500 and 1,800 mm. The enclosures are shipped Worldwide in just a few days and also are made as specials.

Innovative Weld Purge Chambers offer significant attractions over vacuum and glove box alternatives resulting in vast reductions in costs.

Mark Cooper, Fabrication Manager at Shapes Aerospace International recently said: "We use our Argweld ® Flexible Welding Enclosure® along with the PurgEye ® Weld Purge Monitor ® every day for our titanium welding. They are built to last!"

Flexible Welding Enclosure ® videos are available on our YouTube Channel, available in English, German, French, Italian and Spanish.