Tungsten Electrode Grinder: The Tungsten Electrode is one of the most important variables involved in TIG welding. Preparing your Tungsten Electrode correctly will help to improve arc starting, arc stability and consequently weld quality.

Huntingdon Fusion Techniques HFT® have been manufacturing Tungsten Electrode Grinders since the 1980’s.

Just look how far we’ve come…

Above is a picture of one of our older Tungsten Electrode Grinders.

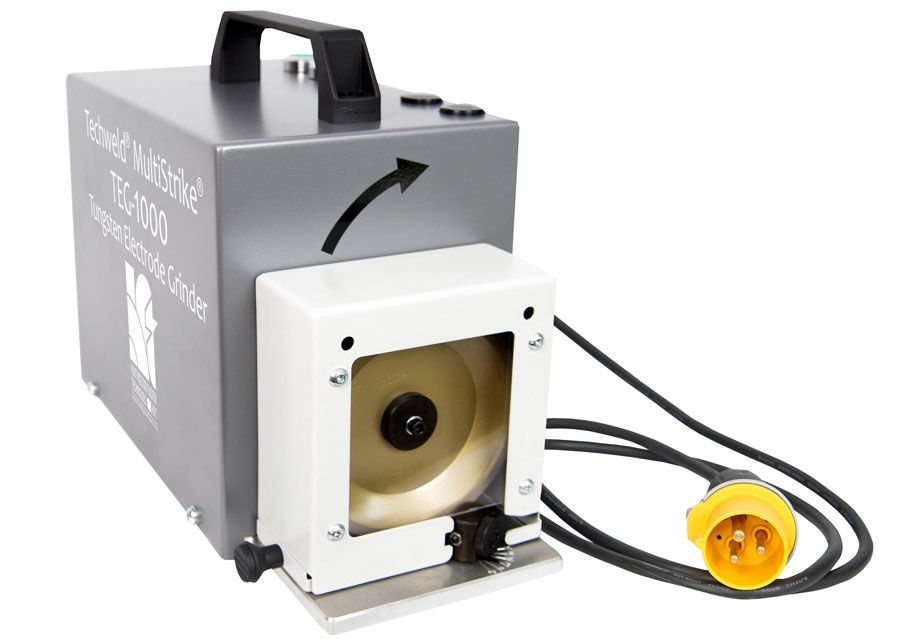

Compared to our state of the art TEG-1000, ensuring TIG welding Tungsten Electrodes have perfectly ground and polished tips.

Although the basic principles haven’t changed, the quality has been upgraded.

The direction of grinding is still longitudinal to avoid any circumferential ridges that might cause current skipping and arc instability.

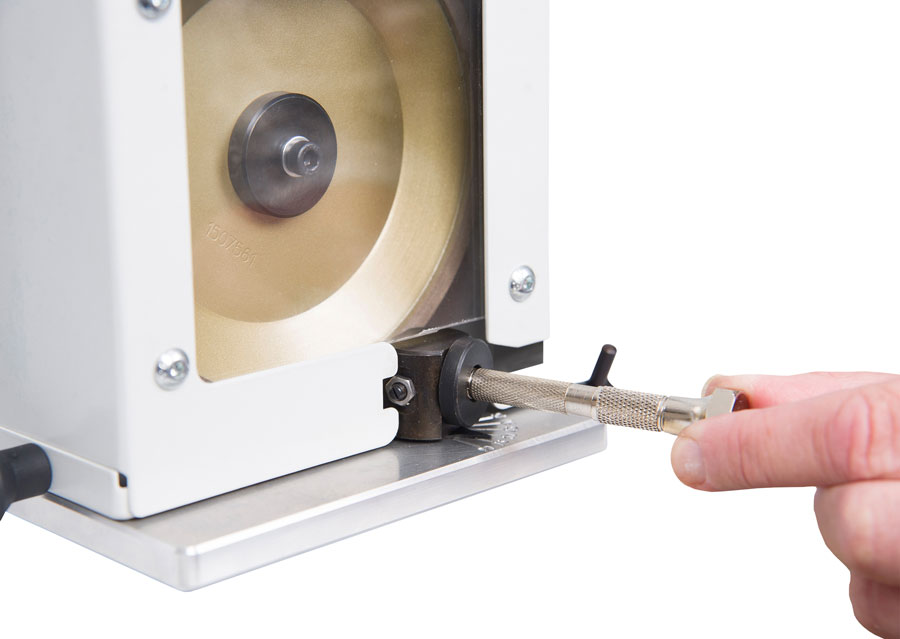

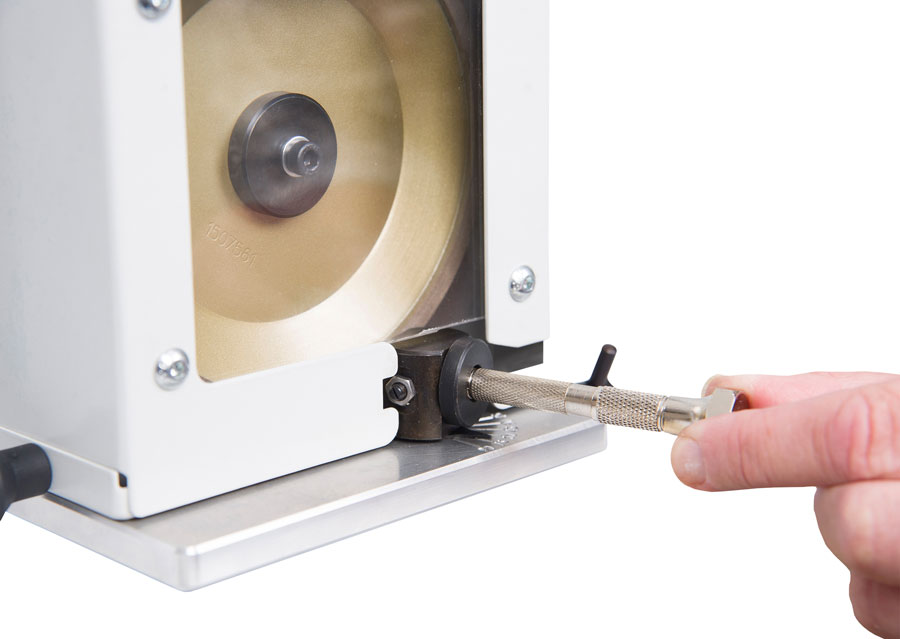

The TEG-1000 Tungsten Electrode Grinder will give repeatable Tungsten Electrode points every time, enabling consistent arc performance and welding results. Sizes 1.0 to 3.2 mm can be ground as standard, with other sizes catered for on request.

Other features include:

Replacement wheels fit all models, the TEG2, TEG3 and the TEG-1000.

TIG welding requires Tungsten Electrodes to have perfectly ground and polished tips. HFT®’s TEG-1000 provides these, time after time, to exactly the same size and shape.

With Tungsten Electrodes ground and polished, mechanised welding can produce identical results every time. With manual welding, the shape of the Tungsten Electrode is just as important. With a correctly shaped tip, the arc can be precisely positioned with none of the preferential arcing experienced when using poorly shaped manually ground tips.

Watch our TEG-1000 Video on YouTube: https://youtu.be/GjXUVsFYTzw.