Titanium Welding: Ti 22 MkII wins first place at Hillsborough Concours Vintage race class.

The Ti 22 MKII was re-built from original drawings and photos. See HFT White Paper WP-271 Titanium in Motor Sport.

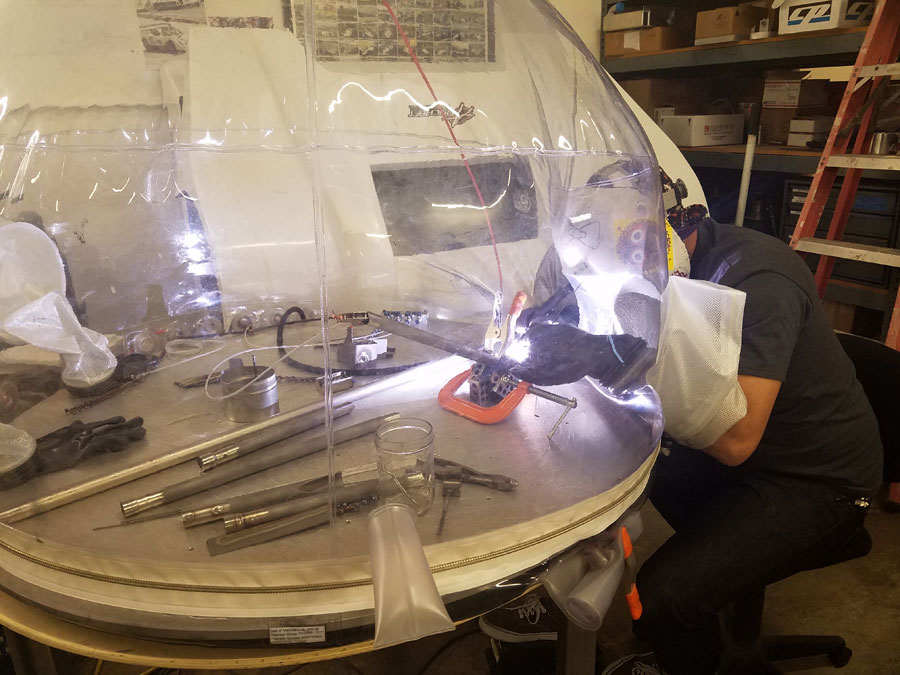

The titanium welding was carried out in an Argweld® Flexible Welding Enclosure, providing a complete inert atmosphere down to as low as 10 ppm.

The lightweight, mostly titanium alloy car, now wins races thanks to the welds made in the HFT® Enclosure.

Here are two photos of the car after winning the First place as the Hillsborough Concours Vintage race class.

Titanium welding inside a Welding Enclosure®

Titanium is a reactive metal and when it is heated during the welding process, it will react with oxygen, forming undesirable compounds.

Flexible Welding Enclosures® offer many attractions over metal glove boxes, including significant reduction in cost.

Welding Enclosures are ideal for small production quantities of items that need total gas coverage as well as single large items with critical joints. A combination of translucent material and optically clear sheet is used depending on the viewing requirements of the customer. Large access zips are fitted to each Enclosure and additional entry points can be provided for operators’ gloves.

A service panel incorporates access ports for welding torches, electrical leads and water-cooling supplies. A purge gas entry port and exhaust valve are also manufactured as standard to vent displaced gas into the atmosphere.

More information on the Argweld® Flexible Welding Enclosures.