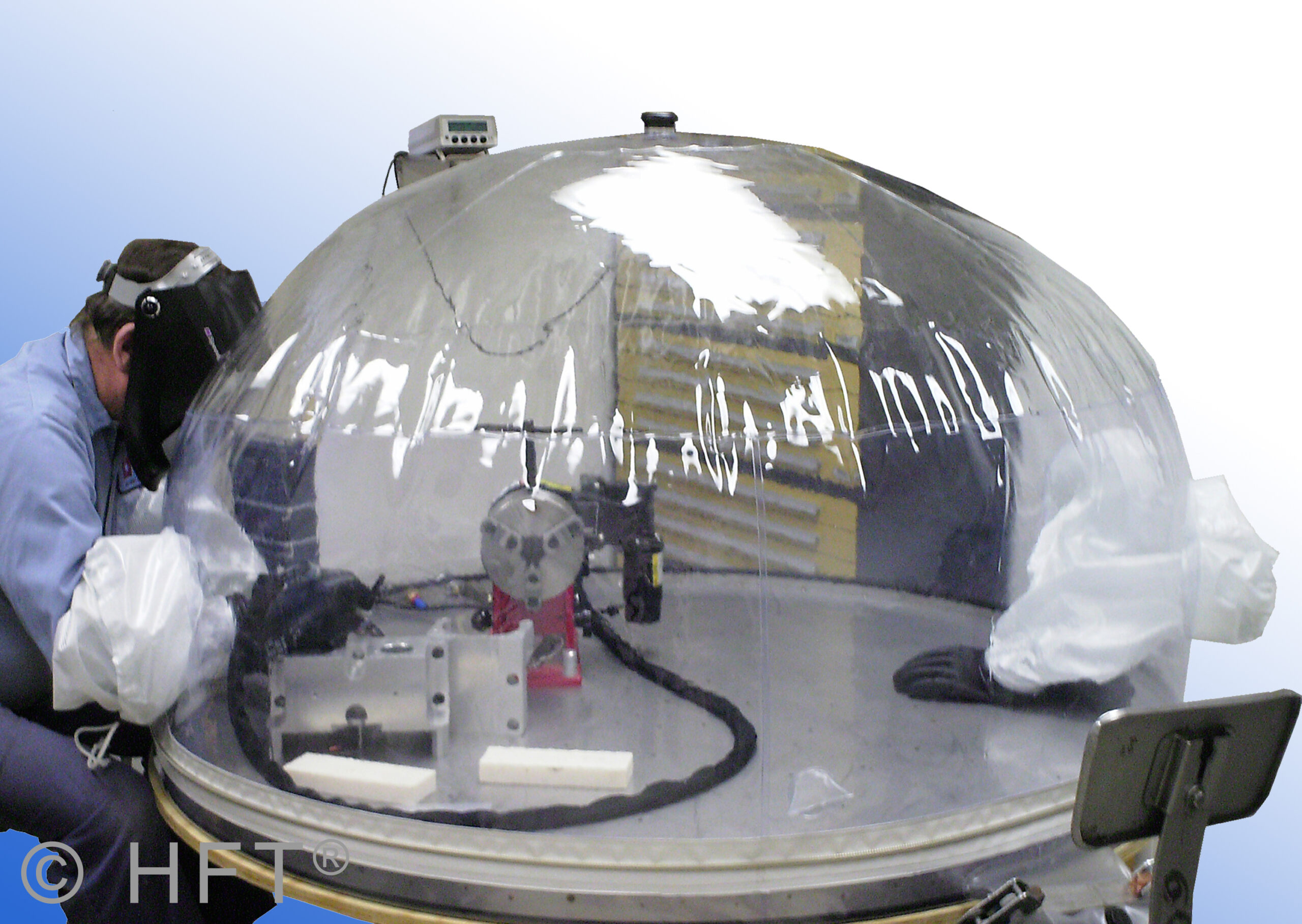

A technical article about the welding of Aerospace quality components in Argweld® Flexible Welding Enclosures®, has just been published online in TubeFirst Magazine, click link below

While welding enclosures or welding chambers have generally been associated with welding Titanium, any company welding stainless steel, chrome steel or nickel alloy components can ensure that they are welded without oxidation and without discolouration.

This eliminates cleaning costs and saves an enormous part of the labour cycle in the manufacturing process.

There can also be a notable savings in the cost of expensive argon gas too, when Tig/GTAW welding inside enclosures.

Another advantage of welding in enclosures, is that welding can be carried out at higher speeds because the weld pool is always protected from oxidation, no matter how fast the welder moves his torch.

Apart from the aerospace industries that have traditionally been associated with chamber welding, the Argweld® Flexible Enclosures® have slowly been accepted by many of the Sports vehicle related industries such as Racing Cars, off road vehicles, bicycles and motor cycles.