Inert gas weld purging is a crucial process in welding, especially for metals prone to oxidation, such as stainless steel and Zirconium alloys. Proper purging displaces oxygen from the weld zone, preventing oxidation, which can compromise the weld’s corrosion resistance and strength. This guide provides seven practical tips for achieving effective weld purging, ensuring high-quality and durable welds.

Achieving a high-quality weld requires careful attention to weld purging, especially when dealing with metals sensitive to oxidation. Inert gas weld purging is essential for displacing oxygen from the weld zone before and during welding. Residual oxygen can lead to a significant loss of corrosion resistance and joint strength, so it's crucial to ensure the purge zone is adequately sealed and monitored. Here are seven tips to help you achieve effective weld purging:

1. Choose a Dependable Sealing Material

The quality of the sealing material is critical. Avoid using low-quality materials such as polystyrene foam, wood, or cardboard, as they can leak, emit contaminants, or even catch fire during the welding process. Instead, opt for specialised purge systems like the QuickPurge® range. These systems use stable, thermally resistant, durable, and non-toxic materials, ensuring an effective seal and a low purge volume (Fig 1).

2. Use a Complete Purging System

Attempting to create a makeshift purging system from available materials rarely succeeds and can lead to time-consuming, non-reusable setups. Investing in a complete purging system with inflatable dams, pre-set gas flow, and pressure controls is better. These systems are designed for multiple uses and are rugged enough for site conditions, significantly reducing purging and welding time. PurgElite® systems, for instance, are fully integrated, flexible enough to traverse 90º bends, and available in sizes between 25- and 600-mm diameter (Fig 2).

3. Establish the Acceptable Oxygen Level in the Purge Gas

Different materials require different oxygen levels in the purge gas to prevent loss of mechanical and physical properties. For instance, stainless steels generally require a lower oxygen level than carbon steel. Knowing the specific requirements for the material you are welding is essential to ensure optimal results.

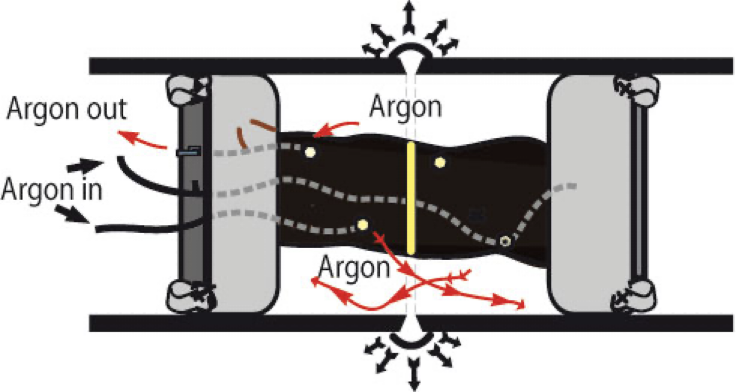

4. Take Care with Gas Flow

Proper gas flow is essential for effective purging. For argon, heavier than air, introduce the gas slowly at the bottom of the weld purge space and discharge it from the highest point. Conversely, lighter than air, helium should be introduced at the top and removed from the base. This approach helps ensure that the air is entirely displaced, reducing the risk of oxidation during welding (Fig 3).

5. Don’t Rush into the Welding Sequence

Ensure that all air has been displaced before beginning the weld. This means achieving a residual oxygen level below 100 ppm for many metals. Rushing into welding without confirming the oxygen level can lead to oxidation, causing the weld to be rejected and leading to expensive rework and production delays. It also risks compromising the corrosion resistance of materials like stainless steel.

6. Use a Purge Gas Oxygen Monitor

Never assume that the purge is complete based on time alone. Leaks, turbulence, or poor-quality purge gas can result in oxygen levels that are too high, causing contamination. The best practice is using a purge gas oxygen monitor to accurately measure and control the oxygen level. Instruments like the PurgEye® Weld Purge Monitors® are designed for site use and can measure oxygen content as low as ten ppm, ensuring that the environment remains free from contamination (Fig 4).

7. Read Published Information About Purging

A wealth of information on weld purging techniques is available. Rather than relying on trial and error, take the time to learn from the experiences and recommendations of others. This can save time, reduce the need for re-welding, and ultimately lead to better weld quality.

References

By following these tips and utilising the right tools and techniques, you can ensure effective weld purging, leading to more robust, more reliable welds.