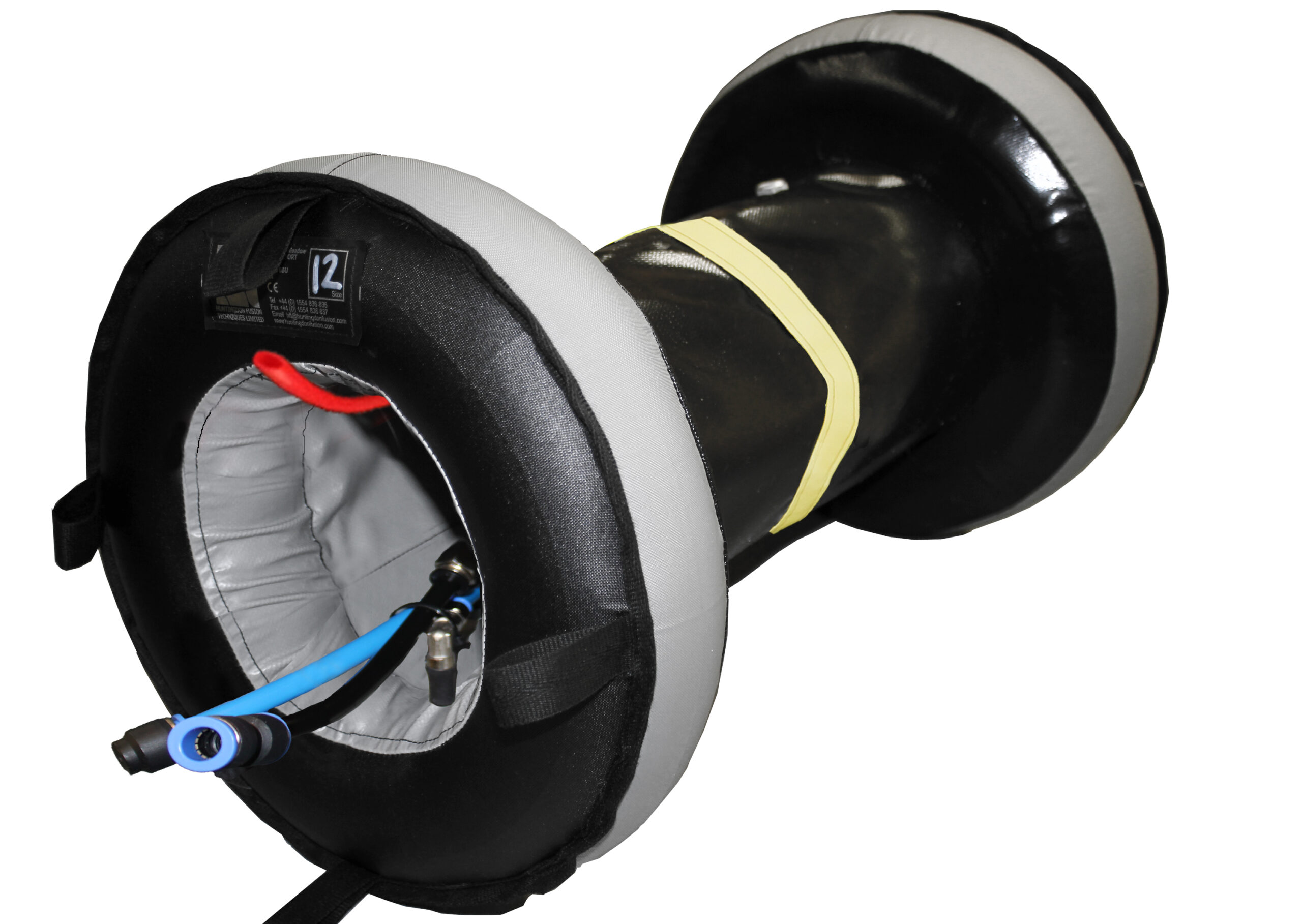

QuickPurge ® Inflatable Tube, Pipe and Pipeline Weld Purging Systems are designed and manufactured in the UK by Huntingdon Fusion Techniques HFT ®.

QuickPurge ® is manufactured with our 40 years of experience in the field of weld purging, we use scientific knowledge and innovation in every product that we manufacture.

Lets see how our QuickPurge ® Systems compare to other types of weld purging methods:

QuickPurge®

- 100% quality product. Our QuickPurge ® Systems are professionally designed, manufactured in the UK and are 100% quality tested. Many other weld purging methods are home made or use poor quality materials.

- Size for size, QuickPurge ® really measure up! QuickPurge ® Systems are available in sizes 6 – 96” (150 – 2,440 mm), which is a much larger range than is practical for others to fabricate.

- QuickPurge® will not pop! To ensure the inflatable dams don't burst, each QuickPurge® System is manufactured as standard with PurgeGate®, a unique innovative valve that regulates the gas flow and restricts pressure. So far we are unaware of anybody else developing an anti burst system to use with inflatable devices.

Competitive Purging System

- Out with the metal. QuickPurge® Systems are designed with no metal fittings, which are likely to interfere with radiography or scratch the inside of pipes when being pulled through the pipeline. Because metal parts are cheaper to manufacture, people tending to try to put a more sophisticated system together, will use the cheaper parts which are in fact likely to cause you difficulties and cost you extra money in the long run.

- They glow in the pipe for up to 20 hours. Each QuickPurge® system is manufactured with RootGlo®, a highly luminescent central band that allows the operator to position the QuickPurge® System quickly and accurately inside the pipe. RootGlo® can be clearly seen through the weld root gap, absorbing enough energy throughout the day to provide up to 20 hours of luminescence inside the pipe. Our RootGlo® positioning strip is stitched both sides in the centre. Those trying to emulate our developments are forced to use adhesive methods that fall off during welding.

- Turn up the heat. Due to the material used on each QuickPurge®, its operating temperature is 250ºC (482ºF) continuous use and up to 280ºC (536ºF) for short periods. They also don't outgas, preventing weld contamination. Lower quality purge devices have been using nylon, which is only resistant to 80º.

- QuickPurge® for the really big financial gain. The advanced design of the QuickPurge® System means that oxygen levels as low as 10 parts per million (ppm) can be reached every time, allowing zero colour welds to be achieved with no loss of corrosion resistance caused by oxidation.

If you are offered other fabricated devices, they will come from resellers and not manufacturers.

HFT®, who are the designers, developers and manufacturers of these weld purging products ensure that their Exclusive Distributors are fully trained in all aspects of the weld purging systems and the subject of weld purging.

QuickPurge®

Don't try to save money on other purging systems. Take a look at our comparison charts. QuickPurge® will pay themselves in less than one weld.