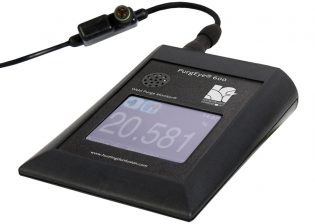

Our all in one, colour touch-screen PurgEye 600 with PurgeNet™ reads from atmospheric, down to 1 ppm oxygen (accurate to 10 ppm).

Here are some of our Frequently Asked Questions.

Q. What is the intended application for the Argweld® PurgEye 600 Weld Purge Monitor®?

For weld quality control in aerospace, semiconductor, pharmaceutical, vacuum, biotech, food and drinks industries where pristine oxide free welds have to be achieved.

Also, applications demanding extremely accurate readings from atmosphere right down to 1 part per million (ppm), such as welds made in titanium, zirconium, duplex steels, nickel alloys and high specification stainless steels.

Q. What sort of sensor is used in the Argweld® PurgEye® 600 Weld Purge Monitor®?

The PurgEye 600 Weld Purge Monitor® uses a solid-state long life sensor of a unique design.

Q. Why do I need software?

The software package, PurgeLog™, is included for those companies who may need to produce quality control documentation to show that the oxygen levels remained below required values for the duration of the weld.

The software allows the user to plot oxygen reading against time, save the information to hard drive and print the data as required.

Q. Can Weld Purge Monitors® only be used when purging with argon?

The PurgEye® Weld Purge Monitors® measure the oxygen level within any gas, not only inert gases. They can be used to monitor the oxygen level when using helium and also semi-inert gases including nitrogen and nitrogen/ hydrogen mixes.

Q. What is PurgeNet™?

The PurgeNet™ facility allows a series of accessories to be added to the Weld Purge Monitor®. One accessory allows control of automatic welding systems to switch the welding process on and off according to pre-set oxygen levels. PurgeNet™ can be used with PurgeLog™ Software to transfer weld purge data for quality control of welds. PurgeNet™ connects to other smart accessories for weld purging, including the external, distance light system, which gives a visual warning during welding in case of rising or falling oxygen levels. Other accessories include a Dew Point Monitor and an audible alarm.