Protecting titanium and stainless steel welds from coming into contact with air whilst they cool prevents oxidation, weld defects and rework.

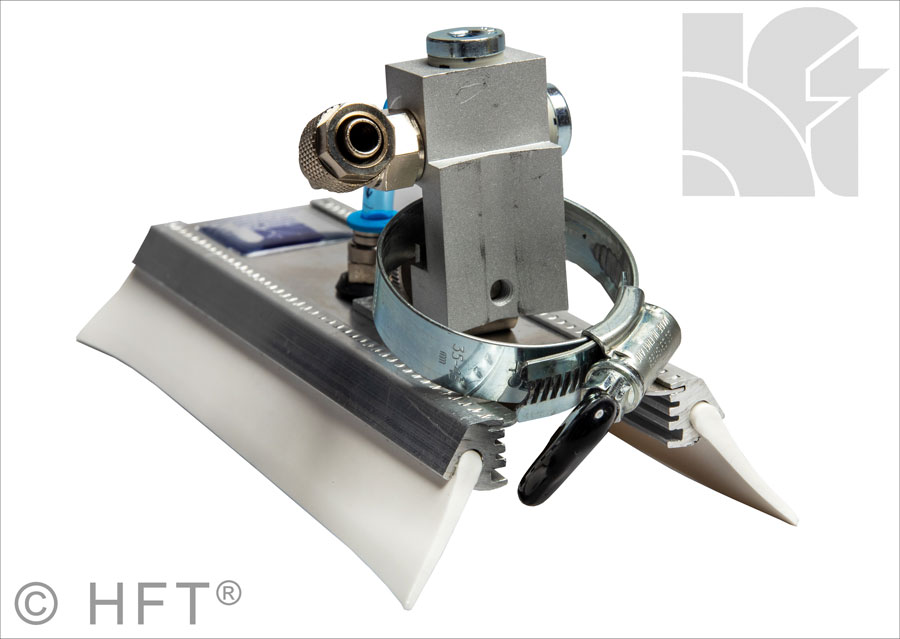

Leaders in Weld Purging Technology, Huntingdon Fusion Techniques HFT® have launched their re-designed Argweld Weld Trailing Shields®, which provide an additional inert gas coverage during welding, preventing the hot metal from coming into contact with air while it cools.

CEO Managing Director, Georgia Gascoyne said: “Along with the new sleek design, our Argweld Weld Trailing Shields® have a NEW Unique clip design, which means the welder can interchange different trailing shield sizes without having to change the welding torch.”

“With our name and logo stamped onto every new Argweld Weld Trailing Shields®, you can be sure the Shield you are using is a HFT design. We manufacture our Argweld Weld Trailing Shields® right here in the UK so we can guarantee quality and 100% craftsmanship.“

The low cost, lightweight Argweld Weld Trailing Shields® will fit any make of TIG, MIG or Plasma (GTAW, GMAW, PAW) welding torch for welding flat sheet or plate and the OD or ID of tubes or pipes. For pipes and vessels the radiused versions are manufactured to suit diameters from 25 mm and upwards.

By using an Argweld Weld Trailing Shields® welds will be left bright and shiny and eliminate discolouration and oxidation. The silicone (side skirt) gasket is resistant to temperatures up to 230ºC.

Titanium and stainless steels are chosen for their corrosion resistant properties in particular and if they are then allowed to oxidise during the weld cycle, expensive post welding cleaning techniques become necessary. Using a Argweld Weld Trailing Shields® guarantees an oxide free, zero colour, bright shiny weld, time and time again.

Made in Wales ‘Manufacturer of the Year’ and Welsh Business Awards – Exporter of the Year.

Huntingdon Fusion Techniques HFT® have a Worldwide Exclusive Distributor Network.

|

|

This Press Release is Succesfully Published in Worldwide Magazines, by clicking the logo you can read the article:

|

Read the published article directly on the website OilVoice. |

|

Read the published article directly on the website Stainless Steel World Americas. |

You are not allowed to use or copy any of this material or content without the written permission of Huntingdon Fusion Techniques HFT®, copyright protected. All rights belong to Huntingdon Fusion Techniques HFT® exclusively. Not for any reproduction without consent.

|