Pipe freezing is fast becoming one of the most efficient ways to make pipe repairs or to carry out pipeline maintenance. By creating an ice plug, fluids inside the pipe can remain present, rather than having to drain down the entire system.

Here are some of our frequently asked questions regarding the Pipe Freezing System, Accu-Freeze™.

Q.

What applications is Accu-Freeze™ designed for?

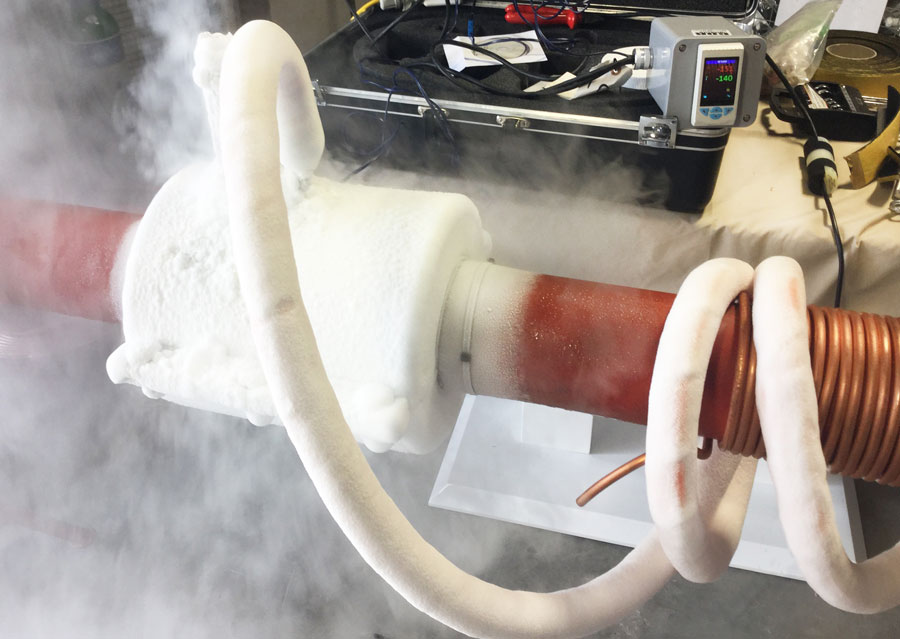

Accu-Freeze™

utilises liquid nitrogen to create the cryogenic temperature necessary to form

ice plugs. Freeze sealing is most often used to isolate a section of a piping

system where no other ready means of isolation (such as valving) is available.

Freeze sealing refers to the process of applying an external refrigerant to a

point in a process in order to cause the formation of a solid internal plug

from the frozen process fluid contained in the pipe.

Q. What size pipes is Accu-Freeze™ suitable

for?

The Accu-Freeze® insulating jacket accommodates pipe sizes from 6 -

12" (150 - 305 mm). Copper coil is used for the smaller sizes. Aluminium

clam shells are available for 2” - 16” (50 mm - 400 mm).

Q. Can I freeze on a weld?

It is not ideal to freeze on a weld unless the weld has been

x-rayed.

Q. Can I freeze contents that are moving within a pipe?

No, the liquid contents of the pipe have to be stationary and non-vibrating

Q. Can I freeze liquids other than water?

Yes, milk and beer are all examples of other liquids that can be frozen. Some liquids containing refrigerants can be frozen too, just check with our Technical Team on the type and % content.

Q. Can I do a freeze either side of the repair joint?

Yes, this is called a double freeze and necessary accessories can be purchased along with the Accu-Freeze™ kit. A double freeze is required when a valve needs replacing for example.

Q. What kind of pipes can Accu-Freeze™ be used on?

Accu-Freeze™ can be used on iron, lead, steel and copper pipes. It is also applicable to plastic pipes, but these will take up to three times longer.

Q. What about bursting or fracturing pipes?

Pipe fractures are not caused by the ice plug or the freezing process. They are caused by a failure to allow enough space between the ice plug and closed connections. This is due to the increase in pressure that is caused by water that is displaced by the ice plug as it grows that can create a ‘hydraulic ram’ if enough space is not allowed.