Focus on Additive Manufacturing

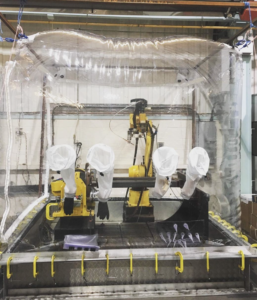

“Additive Manufacturing (AM) is the industrial production name for 3D printing, a computer controlled process that creates three dimensional objects by depositing materials, usually in layers.” – The Welding Institute. The advantages: Additive Manufacturing allows for the creation of bespoke parts, design flexibility, rapid product development and very little wastage. Parts and products can be […]

Read More