Argweld Weld Trailing Shields® are NEW and IMPROVED.

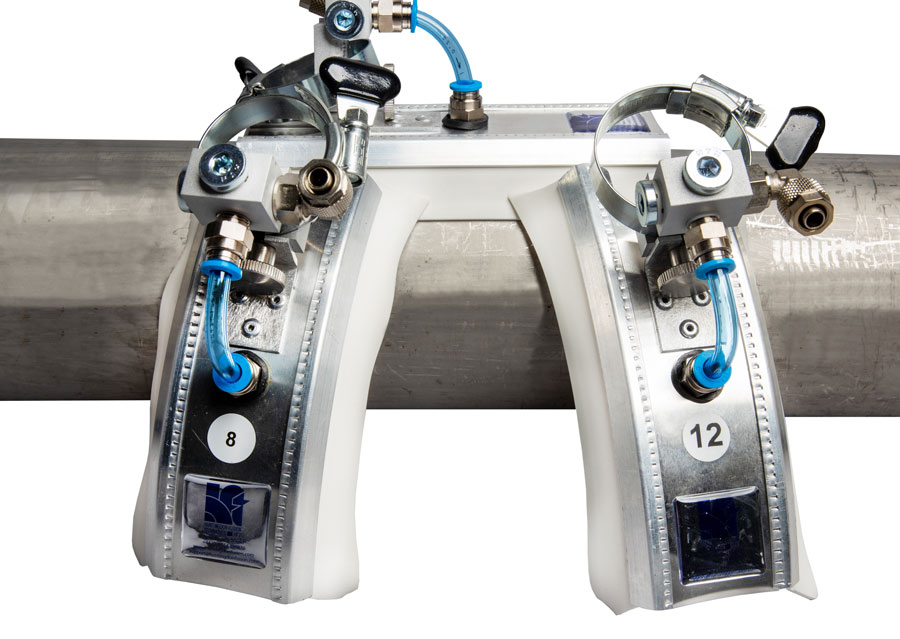

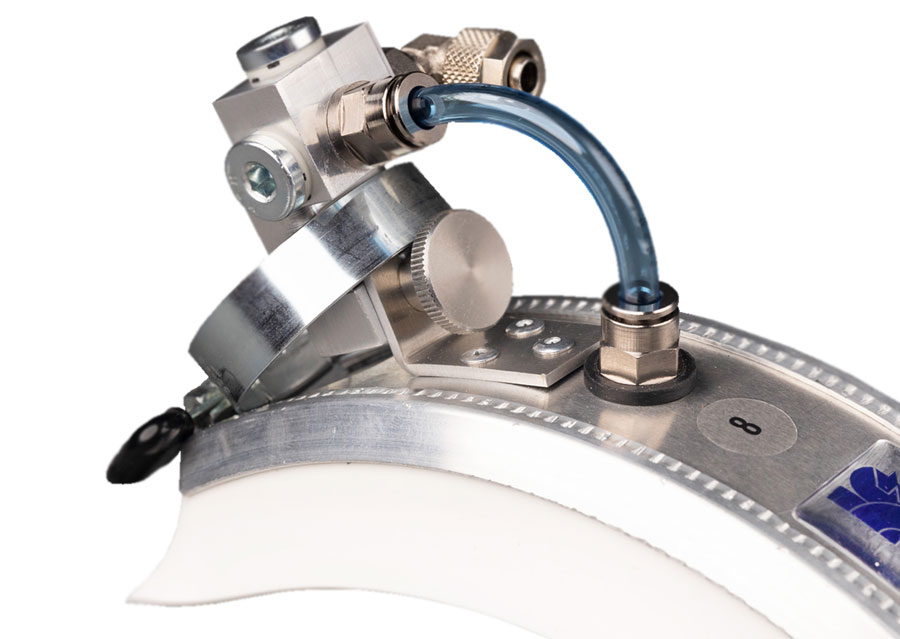

The biggest feature about the new model is the unique torch attachment, which not only can be used by left or right handed welders, but means the welder can change different shield sizes without having to change the welding torch.

Life made easier for welders, left or right handed.

OLD MODEL

NEW AND IMPROVED MODEL

Argweld Weld Trailing Shields® allow the user to weld faster, save money and produce bright, shiny welds.

They provide high quality gas coverage when welding the following materials:

• Titanium, zirconium and cobalt alloys• Duplex steels• Stainless steels• Other reactive metals

Benefits of welding with an Argweld Weld Trailing Shields®:

• Reduce gas consumption• Save re-work• Eliminate wasted material costs and rejected welds due to oxidation

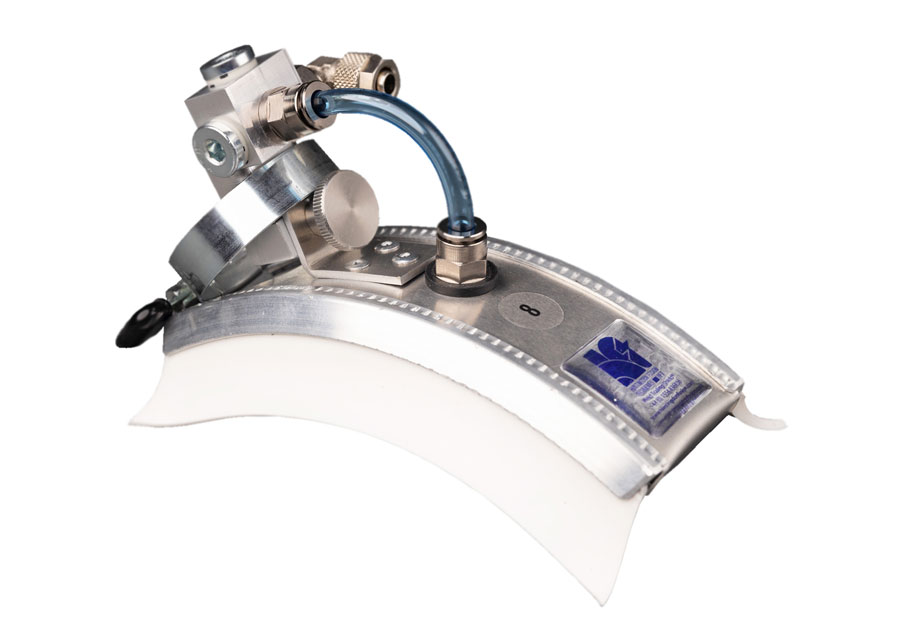

The Argweld Weld Trailing Shield® is connected to the argon gas supply, diffusing gas evenly without turbulence through the multi layers of stainless steel mesh built into the body of the shield. At each side, replaceable silicone rubber side shields provide a barrier to prevent the argon escaping sideways and remaining over the weld metal. As the welding torch is moved forward, the weld remains under an argon gas shield until the welded metal has cooled below its oxidation temperature.

Argweld Weld Trailing Shields® are reusable, with a temperature resistance of up to 230ºC. They prevent re-work, eliminate the need for an expensive purge chamber and allow for faster welding.

Suitable for welding titanium, zirconium, nickel, and cobalt alloys, stainless and duplex steels and other reactive metals. Argweld Weld Trailing Shields® save re-work, reduce gas usage and save wasted material costs by avoiding rejected welds due to oxidation.

There are many other brands similar to our Argweld Weld Trailing Shields® on the market today, make sure your Shield is stamped with the HFT® logo.