Here at Huntingdon Fusion Techniques HFT®, we manufacture all of our Weld Purging Systems and Weld Purge Monitors® with consistent quality of materials and guaranteed craftsmanship.

Awarded ‘Manufacturer of the Year Award 2019’ at the Made In Wales Awards was a true recognition of a company being committed to Quality Manufacturing.

Weld Purge Monitors®

Our PurgEye® Weld Purge Monitors® have been designed and manufactured with scientific knowledge, specifically for welding, providing accurate readings right down to 10 ppm we have a Weld Purge Monitor® to suit every application and budget.

Argweld® PurgElite, QuickPurge, HotPurge, Single Purge Dams

Drastically restricting the volume required to be purged, the use of our Inflatable Pipe Purging Systems will save welders time and inert gas costs, whilst achieving high quality each and every time.

Heat Protective Covers for PurgElite and Inflatable Stoppers

Manufactured from a robust material, the Heat Resistant Covers protect the inflatable dams at each end of the system, with a temperature range of up to 300ºC (572ºF).

Argweld Weld Trailing Shields®

Designed for high quality gas coverage of titanium and stainless steel during welding to prevent oxidation, Argweld Weld Trailing Shields® will fit any make of TIG (GTAW) or Plasma (PAW) welding torch for manual or automatic welding, on flat sheet or plate and the outsides or insides of tubes or pipes.

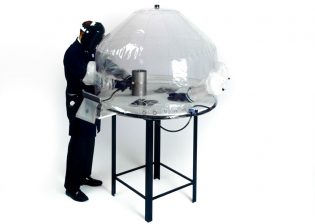

Argweld® Flexible Welding Enclosures®

Flexible Welding Enclosures® has been designed for applications where a rigid chamber may not be economically viable or where space may be at a premium, they are low cost, suitable for welding titanium, zirconium, other reactive metals and for WAAM Additive Manufacturing.

Techweld® Tungsten Electrode Grinder

Ensuring your Tungsten Electrode is sharpened correctly using the TEG-1000 is a more convenient, safer and accurate way than other methods of grinding Tungsten Electrodes.

Pipestoppers® Steel, Aluminium and PlugFast Pipe Plugs Inflatable Stoppers, PetroChem Stoppers and Low Profile Stoppers

These versatile Inflatable Stoppers are used to service a wide diversity of industrial applications, for pipes and ducts as a quick and easy way to stop the flow of gas or liquid, to stop the build up of debris and to prevent ingress of unwanted material or animals.