Repairs and maintenance work required on tubes and pipes can cause unforeseen costs, with entire systems having to be drained down to ensure no liquids are present when repairs are made.

To dramatically reduce operating costs, the Pipestoppers® Division of Huntingdon Fusion Techniques HFT® introduced Accu-Freeze™, the liquid nitrogen (LN2) Pipe Freezing System to create a single ice plug one side of, or double plugs either side of a valve to be changed, for example, in a selected section of pipe or tubing.

Luke Keane, Technical Support for HFT® said: “We have many plumbing and maintenance companies already switching to our Pipe Freezing Systems due to the significant cost savings attached to the avoidance of draining pipes and systems for repairs.”

“Accu-Freeze™ isolates the section of pipe or tube, allowing repairs or modifications to be made without loss of fluid and drainage time.”

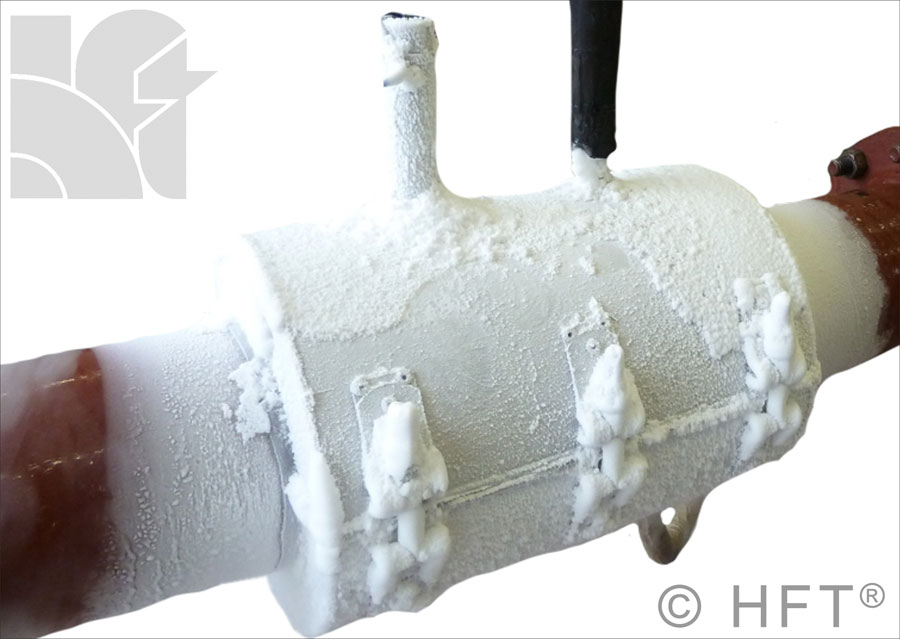

The process involves placing an insulated clam shell jacket over the section to be plugged or simply wrapping copper tube around it. The LN2 is then injected into the tube or jacket, forming an ice plug.

The LN2 injections are automated which reduces the operators’ workload and the amount of LN2 consumed, keeping operating costs low. Accu-Freeze™ can also be operated remotely, which makes it ideal for use inside ‘hot’ nuclear areas where personal exposure must be kept below certain limits.

The primary advantages of the patented Accu-Freeze™ System include:

- The ability to control the pipe wall temperature throughout the freeze process.

- No need to shut off and drain the entire system.

- Creating plugs capable of withstanding 138 bar in diameters up to 12” (300 mm).

- Remote operation, for use in danger areas.

|

|

Huntingdon Fusion Techniques HFT® have a Worldwide Exclusive Distributor network.

This Press Release is Succesfully Published in Worldwide Magazines, by clicking the logo you can read the article:

|

Read the published article directly in the magazine International Tube Association |

| Read the published article directly in the magazine TubeFirst | |

|

Read the published article directly in the magazine GasWorld |

|

Read the published article directly in the magazine Wire and Tube News |

|

Read the published article directly in the magazine Tube News |

|

Read the published article directly in the magazine Interempresas |

You are not allowed to use or copy any of this material or content without the written permission of Huntingdon Fusion Techniques HFT®, copyright protected. All rights belong to Huntingdon Fusion Techniques HFT® exclusively. Not for any reproduction without consent.

|