20,000 PURGEYE® 100's SOLD

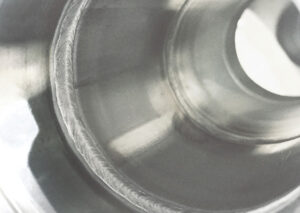

This month marked a huge milestone for us. Since its launch in 2012, we have sold over 20,000 PurgEye® 100 's. Georgia Gascoyne, Managing Director for HFT® said: “Pictured is the very first PurgEye® 100 (Serial Number SN000001). Selling 20,000 PurgEye® 100 Weld Purge Monitors® Worldwide in less than 10 years is an incredible achievement […]

Read More