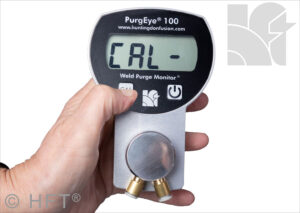

World Standard Weld Purge Monitor®

To ensure non-oxidised, zero colour welds are achieved when welding metals such as stainless, duplex and chrome steels, titanium and nickel alloys, a Weld Purge Monitor® (oxygen monitor) must be used to measure the oxygen level before and during welding. The World Standard PurgEye® 100 IP65 Weld Purge Monitor® designed and manufactured by Weld Purging […]

Read More