Highest Quality Welds made with Lower Costs

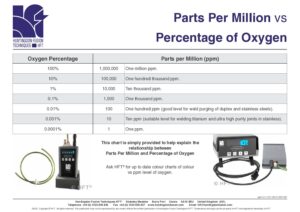

Welding stainless steel, titanium, zirconium, niobium and other metals sensitive to atmospheric gases, requires oxygen levels to be as low as 10 ppm and in some cases, knowledge of dew point level in the shielding and purging gas. Many welds of this nature are still welded with archaic or home-made items to try to shield […]

Read More