Argweld Weld Trailing Shields ® provide an additional inert gas coverage during stainless steel and titanium pipe and sheet metal welding.

The addition of a low cost, reusable Argweld Weld Trailing Shield ® can produce cost saving results.

Here at HFT®, we pride ourselves on product development and with the support of our scientific knowledge and over 45 years of experience we have recently launched our NEW DESIGN Argweld Weld Trailing Shield ®.

What’s new?

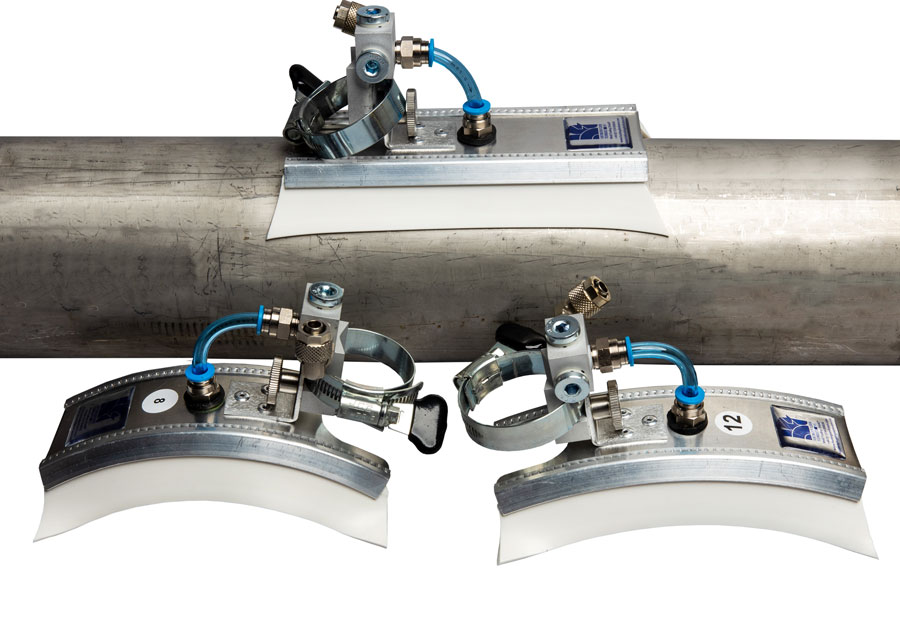

Along with the new sleek design, our Argweld Weld Trailing Shields ® have a NEW Unique clip design, which means the welder can interchange different shield sizes without having to change the welding torch.

With our name and logo stamped onto every new Argweld Weld Trailing Shield ®, you can be sure the Shield you are using is a HFT design, we guarantee quality and 100% craftsmanship. They are built to last.

Each Argweld Weld Trailing Shield® produces perfect gas coverage, smooth gas movement and no leaking with every model carefully and individually tested to ensure quality performance every time. Made in the UK to European Standards and Quality Control Procedures.

View our NEW demonstration video on our YouTube Channel.

Using a HFT® Argweld Weld Trailing Shield

There are many brands of Argweld Weld Trailing Shields on the market today. Make sure your Shield is stamped with the HFT® logo.

The Argweld Weld Trailing Shield® is connected to the argon gas supply, diffusing gas evenly without turbulence through the multi layers of stainless steel mesh built into the body of the shield. At each side, replaceable silicone rubber side shields provide a barrier to prevent the argon escaping sideways and remaining over the weld metal. As the welding torch is moved forward, the weld remains under an argon gas shield until the welded metal has cooled below its oxidation temperature.

Argweld Weld Trailing Shields® are reusable, with a temperature resistance of up to 230ºC. They prevent re-work, eliminate the need for an expensive purge chamber and allow for faster welding.

For manual welding, the welder finds that with this lightweight and low cost tool, there is no difficulty in dragging it along the surface being welded. One further benefit is that it carries the welding torch at 90º to the weld.

If you have purchased a new Argweld® Weld Trailing Shield and would be interested in providing some comparison images, then please get in touch.