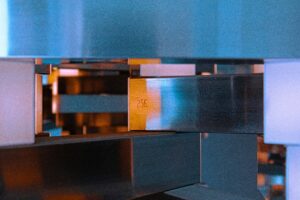

Case Study: Welding of Zirconium and Its Alloys

Zirconium and its primary alloy, Zircaloy, are distinguished by their remarkable physical properties, including mechanical strength, corrosion resistance, and high-temperature stability. These characteristics make them ideal for various industries, such as biochemical, nuclear, aerospace, and petrochemicals. This case study explores the applications of Zirconium alloys, the preparation and techniques involved in welding them, and the […]

Read More