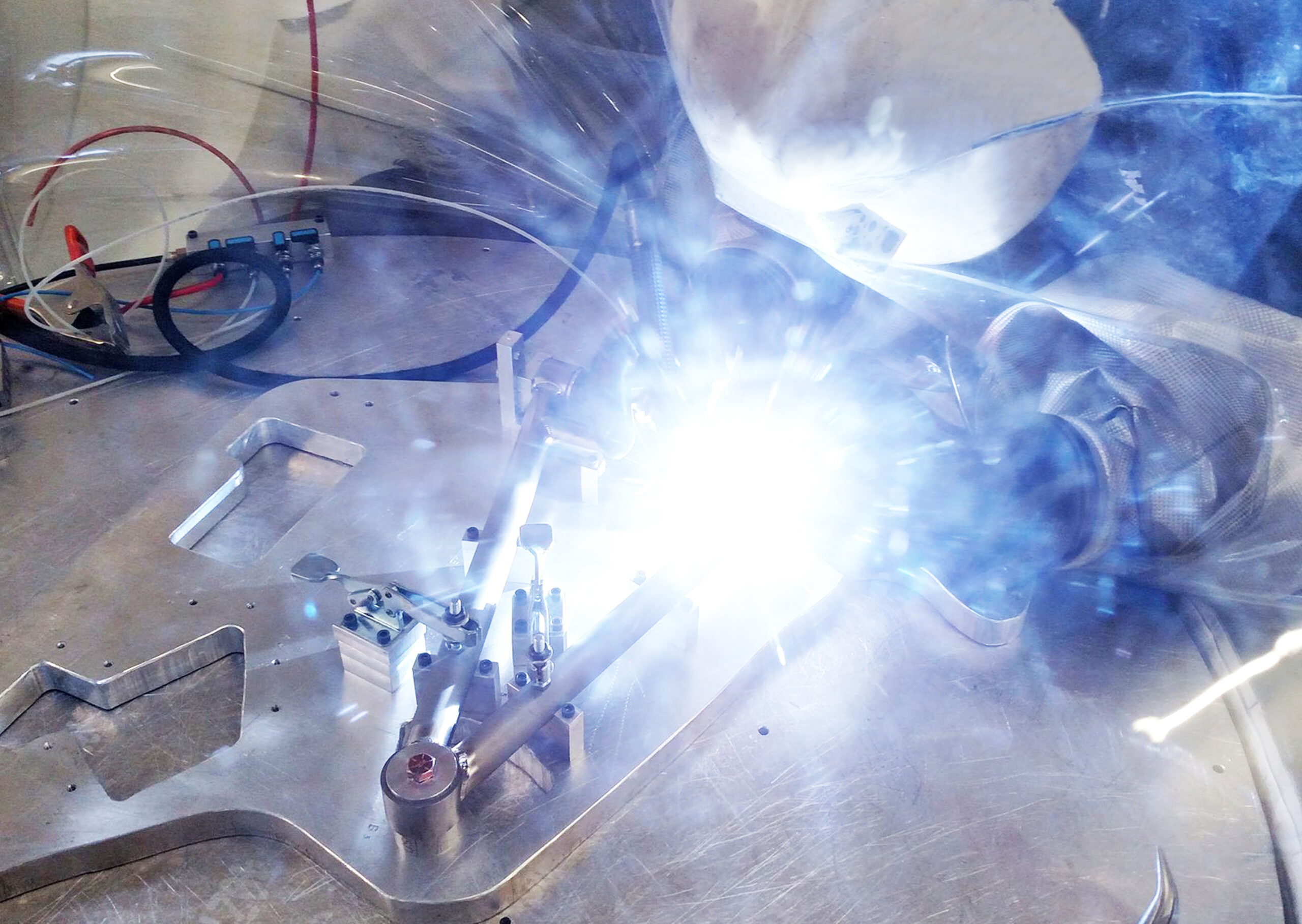

In the power generation and nuclear industry, low and medium alloy steels such as SA 213 T91 and SA 335 P91 are chosen for their high strength, but are often prone to cracking during welding. Pre-heating and post-heating reduces the crack sensitivity.

In order to meet the requirements of inert gas purging when temperatures exceed 200ºC (392ºF). The use of purge systems capable of withstanding such high temperatures for lengthy periods is necessary

HotPurge® has been developed by International Weld Purging Specialists Huntingdon Fusion Techniques HFT®. It is an Inflatable Pipe Purging System for use with High Strength Steel Pipe Joints where pre-and post-weld heating temperatures might be as high as 300ºC (572ºF) for lengthy periods.

Ron Sewell, Chairman for HFT® said: “We are the only manufacturer that has studied materials and designed products suitable for use in weld purging at the high temperatures required during pre- and post-heating.”

“The inflatable seals at each end of HotPurge® systems are manufactured from flexible, yet thermally resistant materials and the central collar is also temperature resistant.”

HotPurge® systems are manufactured in sizes 6 to 88” (150 to 2,235 mm) and can be used repeatedly for weld purging and can keep the oxygen levels below 100 parts per million (ppm) throughout the welding cycle, ensuring oxidation-free welds, without the metallurgical imperfections caused due to rapid heating and cooling.

Once positioned in the pipe and inflated with an inert gas supply, the HotPurge® system seals inside the pipe with inert gas supply displacing the oxygen from within the weld purging zone ready for pre-heating and welding. Each HotPurge® system is manufactured with a Weld Purge Monitor® connection for viewing the oxygen level throughout the welding process.

Each HotPurge® system features PurgeGate®, a revolutionary device to prevent over inflation of, and damage to the inflatable dams. The innovative HotPurge® system also incorporates RootGlo®, a central band for easy positioning inside the pipe, which will illuminate inside the dark pipe for up to 20 hours.

Made in Wales ‘Manufacturer of the Year’ and Welsh Business Awards – Exporter of the Year.

Huntingdon Fusion Techniques HFT® have a Worldwide Exclusive Distributor Network.

|

|

This Press Release is Succesfully Published in Worldwide Magazines, by clicking the logo you can read the article:

|

Read the published article directly on the website OilVoice. |

|

Read the published article directly on the website Canadian Fabricating and Metalworking. |

|

Read the published article directly on the website Stainless Steel World Americas. |

You are not allowed to use or copy any of this material or content without the written permission of Huntingdon Fusion Techniques HFT®, copyright protected. All rights belong to Huntingdon Fusion Techniques HFT® exclusively. Not for any reproduction without consent.

|