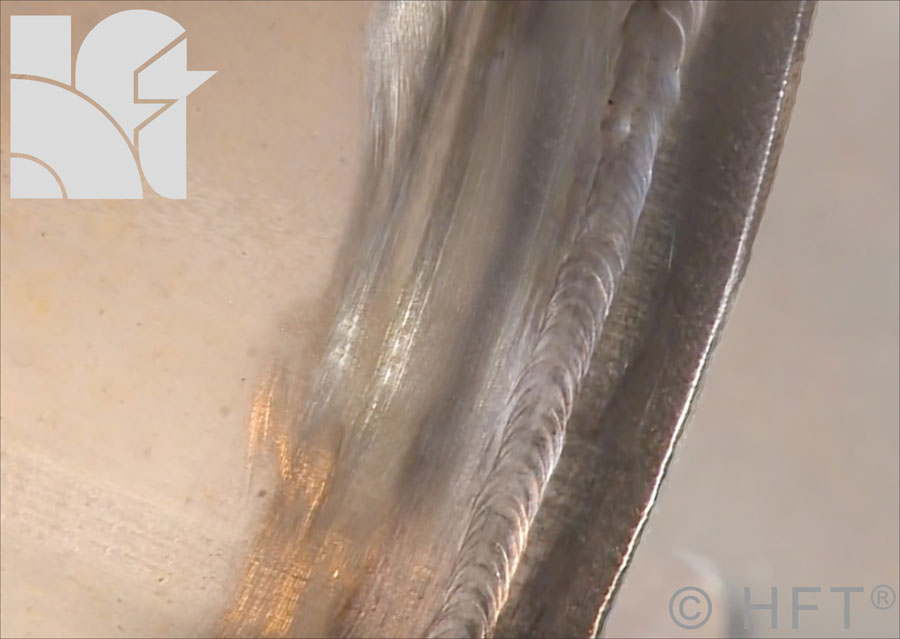

When welding tubes and pipes made of alloys such as stainless, duplex and chrome, it is important to eliminate the oxygen internally with an inert gas. This will help prevent oxidation, discolouration and will ensure a good internal weld profile.

Weld Purging long pipelines can be costly and time consuming, so restricting weld purge volumes will achieve huge savings in time and inert gas.

Huntingdon Fusion Techniques HFT® design and manufacture PurgElite®, a range of low cost Tube and Pipe Purging Systems to achieve a clean, oxide free, zero colour weld in just minutes, available from 1” (25 mm).

Georgia Gascoyne: “2020 marks our 45th years of innovation, design and manufacturing expertise in the field of tube and pipe purging systems. Our PurgElite® Systems help achieve a clean, oxide free, zero colour welds.

“Manufactured to suit pipe diameters from 1” to 24” (25 – 600 mm), PurgElite® are made of low outgassing rate materials, which gives them the ability to produce high quality welds in tubing and piping.”

PurgElite® create a seal either side of the weld. The systems are inserted in the pipe and positioned with the aid of the luminous RootGlo®. When the gas flow is started, the dams inflate, seal inside the pipe and argon then purges the interspace automatically. A Weld Purge Monitor® connection is standard on each PurgElite®, so the welder can monitor the oxygen content of the purge volume throughout the entire welding process.

Each PurgElite® features IntaCal®, a purge gas feed device, which means there is no complicated valving for the operator to adjust and set. A centrepiece glow positioning indicator RootGlo® comes as standard to ensure the system can be positioned accurately inside the tube or pipe.

HFT®’s innovative PurgeGate® Valve is available as an accessory, a unique one way valve suitable for all types of Inflatable Pipe Weld Purging Systems. PurgeGate® regulates the gas flow and pressure during weld purging to prevent the dams from over inflating and bursting.

Heat Resistant Covers with a rating up to a temperature of 300ºC are available as accessories to protect the inflatable dams. These are attached with ties sewn into the covers.

By using PurgElite® Tube and Pipe Purging Systems companies can save significant amounts of money in both time and inert gas costs.

HFT® offer a live demonstration where required and they can send a return on investment chart to show you how quickly it pays to use up to date technology from the very first weld.

Made in Wales – Manufacturer of the Year 2019!

Huntingdon Fusion Techniques HFT® have a Worldwide Exclusive Distributor Network.

|

|

This Press Release is Succesfully Published in Worldwide Magazines, by clicking the logo you can read the article:

|

Read the published article directly in the magazine OilVoice. |

You are not allowed to use or copy any of this material or content without the written permission of Huntingdon Fusion Techniques HFT®, copyright protected. All rights belong to Huntingdon Fusion Techniques HFT® exclusively. Not for any reproduction without consent.

|