CMV Steels (chromium / molybdenum / vanadium) are widely used for their high temperature creep properties especially in the steam turbine industries.

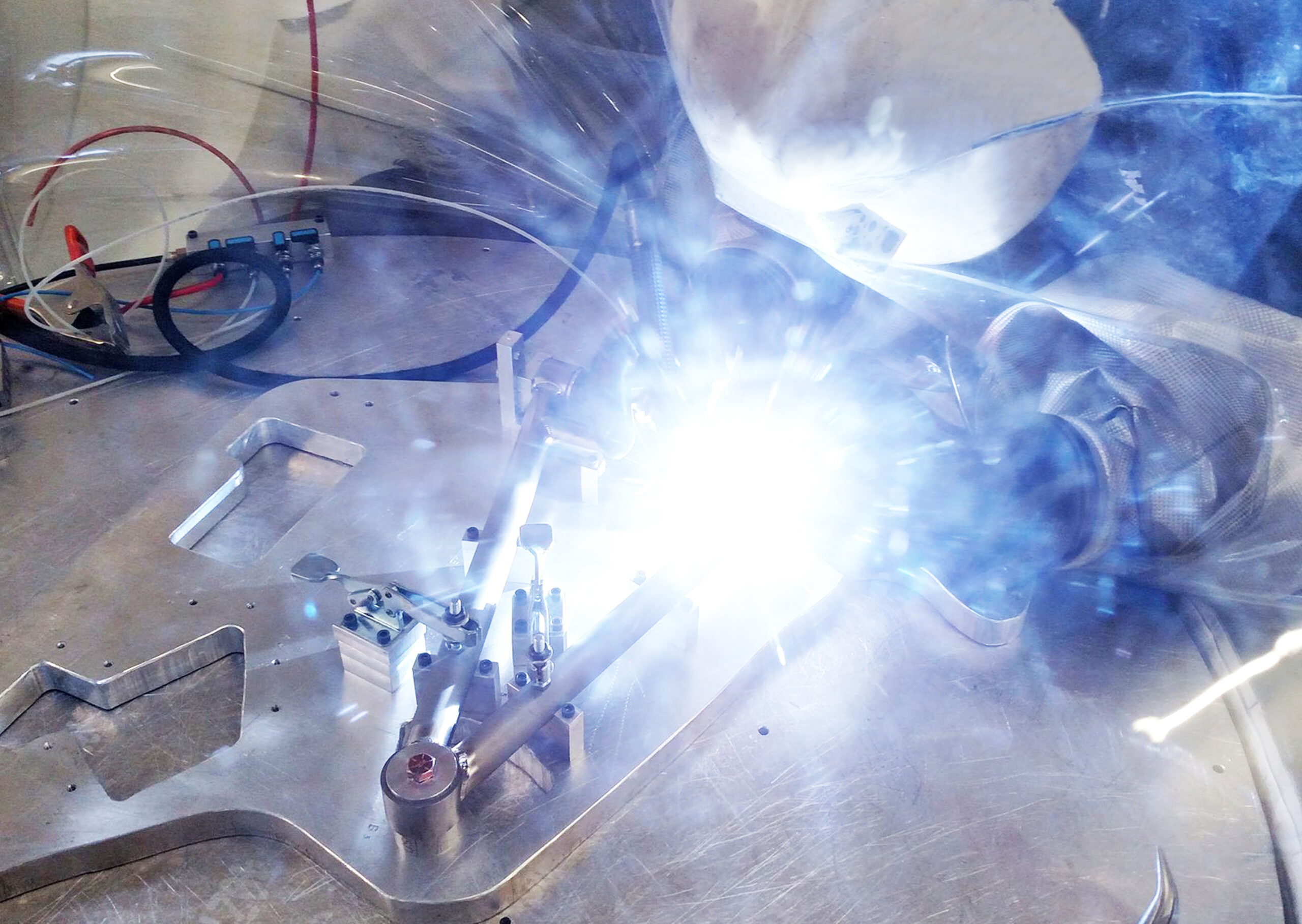

Both pre and post weld heat treatment is necessary to achieve the optimum mechanical strength, but temperatures up to 300ºC (572ºF) must be maintained for lengthy periods. To prevent oxidation, the inside of piping needs to be purged continuously using a specialised pipe weld purging system.

Huntingdon Fusion Techniques HFT® has designed and developed HotPurge® Pipe Purging Systems capable of operation at these elevated temperatures.

Georgia Gascoyne, CEO for HFT® said: “It is no longer practical or cost-effective to fill whole pipe lengths with inert gas; restricting the weld purging zone is the best option. Argweld® HotPurge® Systems allow the purge to be safely continued for up to 24 hours whilst pre-heating, welding and post weld heat-treating with the purge system remaining in place.”

Once positioned in the pipe and inflated with an inert gas supply, the HotPurge® System seals inside the pipe with inert gas supply displacing the oxygen from within the weld purging zone ready for pre-heating and welding. Each HotPurge® System is manufactured with a Weld Purge Monitor® connection for viewing the oxygen level throughout the welding process.

Each HotPurge® System features PurgeGate®, a revolutionary device to prevent over inflation of, and damage to the inflatable dams. The innovative HotPurge® System also incorporates RootGlo®, a central band for easy positioning inside the pipe, which will illuminate inside the dark pipe for up to 20 hours.

Manufactured in sizes 6 to 88” (150 to 2,235 mm) HotPurge® Systems can be used repeatedly for weld purging and can keep the oxygen levels below 100 parts per million (ppm) throughout the welding cycle, ensuring oxidation-free welds, without the metallurgical imperfections caused by exposure to too much oxygen.

Huntingdon Fusion Techniques HFT® have a Worldwide Exclusive Distributor Network.

|

|

This Press Release is Succesfully Published in Worldwide Magazines, by clicking the logo you can read the article:

|

Read the published article directly in the magazine OilVoice |

|

Read the published article directly in the magazine Wire and Tube News |

|

Read the published article directly in the magazine Tube News |

You are not allowed to use or copy any of this material or content without the written permission of Huntingdon Fusion Techniques HFT®, copyright protected. All rights belong to Huntingdon Fusion Techniques HFT® exclusively. Not for any reproduction without consent.

|