Contractors and Maintenance Personnel involved in repairing pipework in buildings and other constructions have long been beset with the problem of making repairs on tubes and pipes when they are full of fluid and may not be economically viable to drain.

Now the Accu-Freeze™ Pipe Freezing System is able to freeze a plug in fluid either side of a repair zone, isolating it, to allow work to be carried out without draining the whole system.

Luke Keane, Technical Support at HFT® said: “Accu-Freeze™ utilises liquid nitrogen (LN2) in a controlled way to freeze stationary liquids in a selected section of pipe or tube.

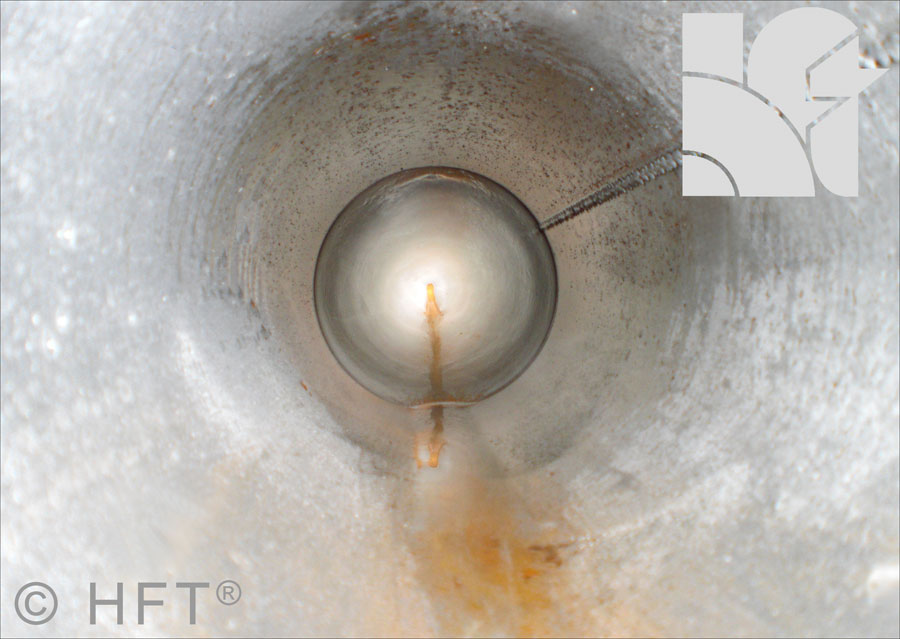

By controlling the surface temperature of the pipe or tube, Accu-Freeze™ can accurately and safely form an in-line ice plug, capable of withstanding 136 bar in diameters up to 12” (300 mm).”

To form an ice plug, the water or liquid inside the pipe or tube is brought to a static condition and a specially designed insulated jacket is placed around the section to be frozen, upstream from the repair zone.

To form an ice plug, the water or liquid inside the pipe or tube is brought to a static condition and a specially designed insulated jacket is placed around the section to be frozen, upstream from the repair zone.

Once the plug is formed, maintenance and repair can take place without draining or shutting off the entire system. The controlled ice plug only forms beneath the Accu-Freeze® jacket, it does not expand outside of this area and does not create enough pressure to affect the integrity of the pipe.

The primary advantages of the patented Accu-Freeze® System include the increased freezing capability of LN2 and the ability to control the pipe wall temperature throughout the freeze process.

The LN2 injections are automated which reduces the operators workload and reduces the amount of LN2 that is consumed, reducing operating costs. Accu-Freeze® can also be operated remotely, which makes it ideal for use inside ‘hot’ nuclear areas where personal exposure must be kept below certain limits.

The Accu-Freeze™ technique is able to freeze large diameters and control the entire freeze process, remotely if necessary.

For more information, please contact:

| Press: | michaelareay@huntingdonfusion.com |

| Sales: | hft@huntingdonfusion.com |

| Web: | www.huntingdonfusion.com |

| Tel.: | +44 1554 836 836 |

This Press Release is Succesfully Published in Worldwide Magazines, by clicking the logo you can read the article: