Thick wall chrome steel pipe joints, as used in the power industry for high pressure high strength pipe work, need to be pre-heated for welding and probably need a post weld heat treatment too.

Weld joints of this nature need to be purged of oxygen and welded in an inert gas atmosphere, to prevent oxidation, slag formation etc., that leads to loss of corrosion resistance and undesirable change to the metallurgy.

With the high temperatures and length of time at temperature needed in the pre-heat, weld and post heat treat cycles, most weld purging systems are unsuitable.

However, Huntingdon Fusion Techniques, HFT®, has now developed "HotPurge®" Pipe Purging Systems, for use up to 300ºC (572ºF) for 24 hours.

HotPurge® is based on the company's world famous QuickPurge® design that has been in wide use for many years, but adapted for use at high temperatures.

This system is available for pipe internal diameters (i.d.) from 6 – 88" (152 – 2,235 mm). Each Hotpurge™ is made to size and has a tolerance of +/- ½" (12 mm) because of the restrictions of heat proofing material.

Features of the HotPurge®

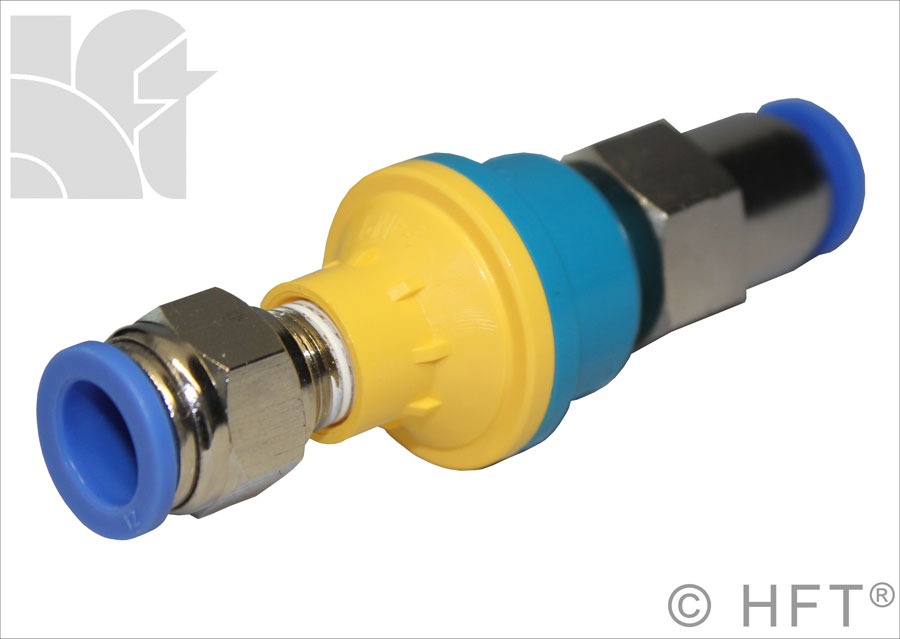

PurgeGate® is a clever, world wide patented invention that allows users to simply connect the Hotpurge™ system to any source of compressed inert gas and simply turn it on to whatever flow or pressure they wish.

PurgeGate® will protect the dams from over inflation or bursting due to over pressurisation and allow the user to deliver whatever flow they like, using the one gas source.

No matter how high the user raises the pressure in order to deliver more flow, PurgeGate® prevents the pressure going to the inflatable dams, but allows the increased flow to make a faster purge.

PurgeGate® is guaranteed for life.

HotPurge® Pipe Purging Systems can be used over and over again for specialist weld purges on power industry piping, that will keep the oxygen levels below 100 parts per million throughout the welding cycle.

Published in these magazines, click the image to see the article