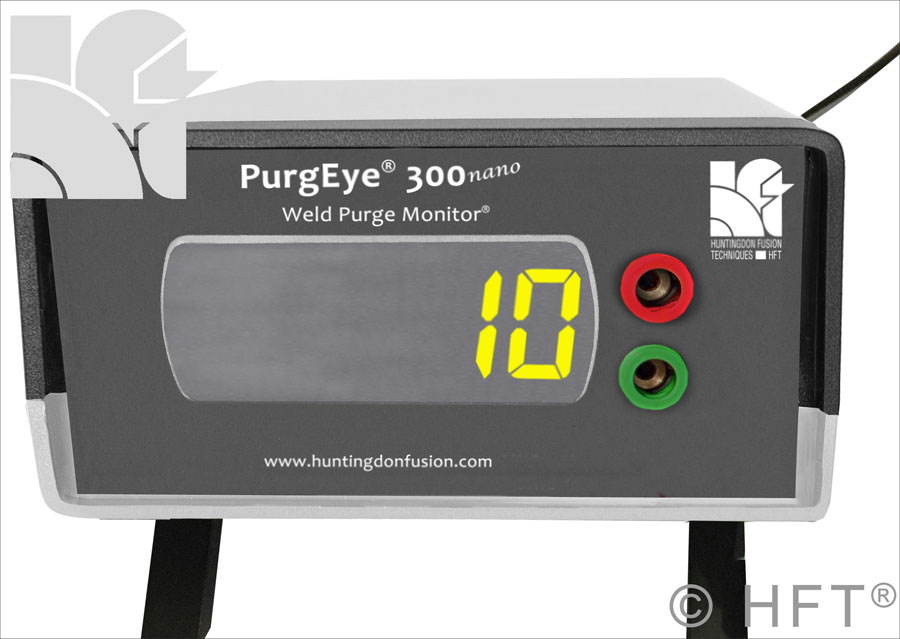

PurgEye® 300 Nano Weld Purge Monitor®

Launched today, The PurgEye® 300 Nano Weld Purge Monitor® is a sensibly priced instrument for measuring Oxygen levels down to 10 ppm (Parts Per Million).

Designed specifically for welding and quality personnel who are responding to the latest quality control standards for lower oxygen levels, this new Weld Purge Monitor® is suitable for weld purging of all Stainless, Duplex and Super Duplex steels as well as Titanium, Zirconium and Nickel alloys.

In addition to its use for the weld purging of tube and pipe joints, either with manual or orbital welding techniques, the PurgEye® 300 Nano can also be attached to welding chambers, boxes and enclosures to ensure that the internal atmosphere is reduced to 10 ppm of Oxygen or less.

Furthermore, this small, lightweight instrument is so accurate that it can be used to check the quality of weld purge gases at source as well as checking for leaks in gas purge lines to obtain the ultra clean, high purity weld joints that are in demand.

Furthermore, this small, lightweight instrument is so accurate that it can be used to check the quality of weld purge gases at source as well as checking for leaks in gas purge lines to obtain the ultra clean, high purity weld joints that are in demand.

Quality standards for pristine tube and pipe welds in many process industries are calling for lower and lower oxygen levels to ensure that oxidation and discolouration are reduced to the barest minimum to cut down cleaning and grinding costs and to provide the correct quality welds for critical welds in industries such as Semiconductor, Biofuels, Food and Drinks, Pharmaceuticals and so on.

This entry level, low cost instrument has no knobs, no buttons, no controls, pump, no moving parts and no programming so it is a truly plug and play, easy to use instrument for very accurate readings right down to 10 parts per million.

The specially, unique new style long life sensor has no repair, refurbishment or calibration costs by eliminating the need for changing and calibrating of sensors as used in wet cell technology.

The PurgEye® 300 Nano is the latest instrument to be launched as part of a complete family of five different Weld Purge Monitors® for different applications.

Click here to send us a message