Our Flexible Welding Enclosures® are in use throughout the Aerospace Industry. These low cost welding chambers provide a complete inert gas coverage when welding components.

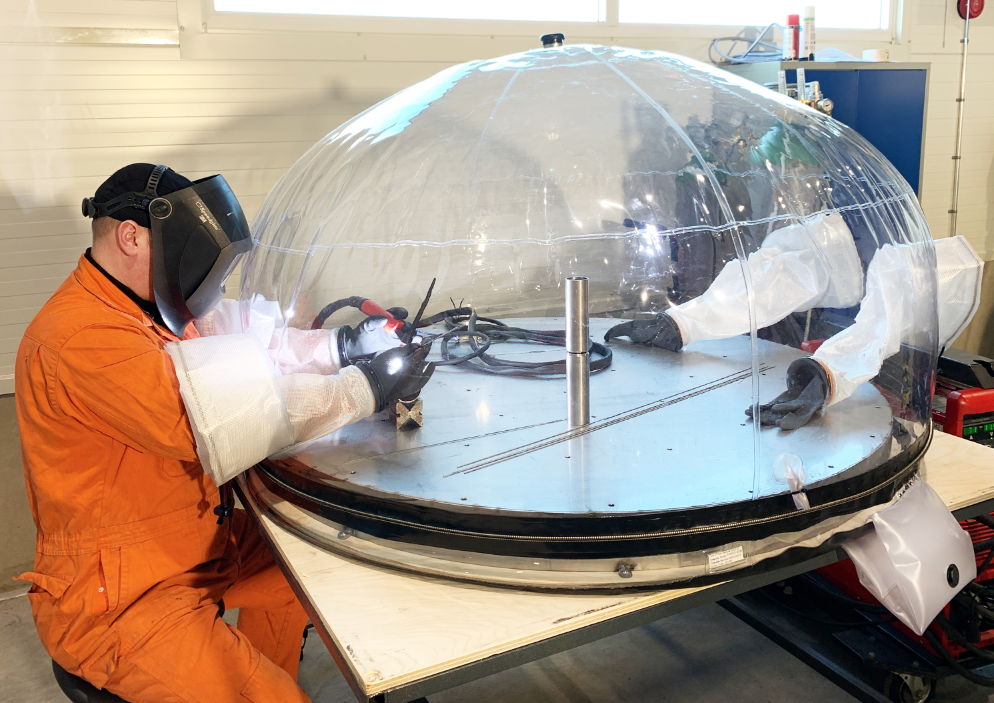

Pictured is a European customer involved in the aerospace industry, welding Titanium, Zirconium and Tantalum.

Argweld® Flexible Welding Enclosures® have been supplied to many notable names in the Aerospace, Sports Vehicle and Medical industries as a means of obtaining a Welding Enclosure quickly for fast turnaround of work, instead of the lengthy process of purchasing and using metal chambers.

Our Flexible Welding Enclosures® have been designed to provide an inert atmosphere for the welding of reactive metals such as titanium, zirconium, nickel alloys and stainless steels, where a rigid chamber may not be economically viable or where space may be at a premium.

The welding of titanium and nickel alloy aero engine parts demands greater attention to cleanliness and requires an inert gas shielding to prevent oxidation and metallurgical problems arising therefrom.

The Welding Chambers are manufactured from UV-resistant polyvinyl chloride (PVC) and are a highly effective device for welding with oxygen levels down to 10 ppm.

The encloses are manufactured with two sets of glove ports as standard and the upper half of the enclosure is optically clear, providing excellent welding vision. A fitted entry lock makes it possible to take small parts in or out of the enclosure without affecting purge quality. Special Enclosures can also be manufactured to suit various applications.

"We use our Argweld® Flexible Welding Enclosure® along with the PurgEye® Weld Purge Monitor® every day for our titanium welding. They are built to last!"

Mark Cooper Fabrication Manager Shapes Aerospace International