Weld Purging Experts Huntingdon Fusion Techniques HFT ®’s range of Weld Purging Equipment are the perfect solution to achieving clean, bright, oxide free stainless steel, titanium and zirconium welds.

Ideal for a variety of pipe sizes, Weld Purge Film® Kits can be used on pipe diameters up to 900 mm (36”) and for temperatures up to 300ºC (572ºF) without the material burning or coming loose and losing the weld purge.

Weld Backing Tape® is a common material used where manual welding cannot control the weld root profile sufficiently, or when an automatic weld process is unable to reach optimum speeds while still obtaining satisfactory underbeads.

HFT Glass Fibre Backing Tape supports and protects the weld root from oxidation. It will trap the inert gas from the weld torch to hold the gas surrounding the weld pool, effectively providing a back purge facility, available in four grades for use up to 600 Amps.

The low cost, lightweight Argweld® Weld Trailing Shields® will fit any make of TIG, MIG or Plasma (GTAW, GMAW, PAW) welding torch for welding flat sheet or plate and the OD or ID of tubes or pipes. For pipes and vessels the radiused versions are manufactured to suit diameters from 25 mm and upwards.

Providing an additional inert gas coverage during and after welding, Argweld Weld Trailing Shields® help to produce bright, shiny, oxide free welds time and time again and eliminating the expensive post weld cleaning process.

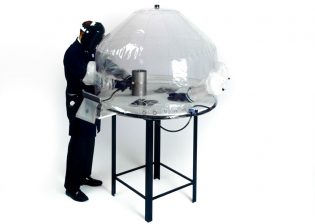

Standard and specially made Welding Enclosures are available for a fraction of the cost of a rigid welding chamber, providing a technically viable option to the very expensive metal chambers and purge boxes.

The state of the art welding chamber, also known as an argon chamber, offers many advantages over a rigid chamber, with rapid purge times down to as low as 10 ppm.

This high quality piece of weld purging equipment has been highly rated by customers worldwide in use within industries including aerospace, racecar, titanium bicycle manufactures and wire arc additive manufacturing.