Tungsten Electrode Grinder: Correctly preparing each Tungsten Electrode for welding is crucial. It is one of the most important variables in TIG / GTA welding and each Tungsten Electrode must be ground properly to improve arc starting, stability and subsequently weld quality.

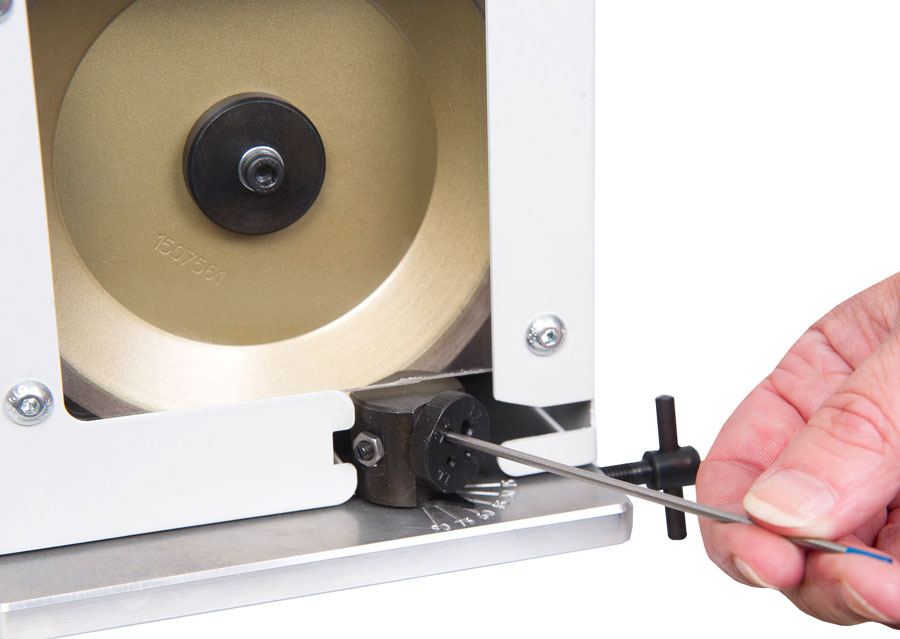

Manufactured with a diamond wheel, the TEG-1000 Tungsten Electrode Grinder from Huntingdon Fusion Techniques HFT® will ensure the grinding of each Tungsten Electrode results in clean and smooth finishes, with no splintering and eliminating arc jumping.

Here are some of our Frequently Asked Questions!

Q. Tell me more about the TEG-1000?

The TEG-1000 Tungsten Electrode Grinder is a low cost, fast return on investment tool, that will grind repeatable Tungsten Electrode points every time, to exactly the same size, surface finish and shape.

Q. What size Tungsten Electrodes can the TEG-1000 be used for?

Sizes from 1.0 to 3.2 mm can be ground with the standard collet provided. Other sizes and short lengths can be ground with the individual collet sets as required.

Q. Why does the TEG-1000 require a diamond wheel?

The diamond wheel grinds the Tungsten Electrodes’ longitudinally and with a much smoother finish than other types of wheels. This prevents arc flicker or wander caused by circumferential lines or ridges found on Tungsten Electrodes, which have been ground incorrectly.

Q. What is the return on investment?

The cost saved in grinding materials alone can provide rapid payback for the TEG-1000 Tungsten Electrode Grinder. In addition because of the softer way that electrodes can be ground on the TEG-1000 with the diamond wheel, the electrodes are not overheated as they can be with other grinding methods and materials, so they do not split, thus saving on wastage of electrodes. Using the Collet/Pin Vice accessory, short lengths can be ground, whereas welders tend to discard 50% of the length of each tungsten electrode as they become too short to hold for normal manual grinding methods. The diamond wheels last many times longer than the ‘soft’ silicon carbide wheels.

Q. What Tungsten Electrode would you recommend for the TEG-1000?

The TEG-1000 will grind all standard Tungsten Electrodes for TIG/GTAW, Plasma/PAW and resistance welding. We highly recommend MultiStrike® Tungsten Electrodes which, to our knowledge, are the only fully traceable tungstens available. They have no radiotoxic thoria that the red tipped tungsten electrodes have. When used in automatic and manual welding processes, operators experience less down time and can achieve full weld penetration with less heat input and up to ten times greater arc striking before re-grinding is necessary.