Supporting the liquid weld root with a high temperature Backing Tape will ensure minimal oxidation and will require much less post-weld cleaning.

Argweld® glass fibre Weld Backing Tape® from Huntingdon Fusion Techniques HFT® supports weld roots and eliminates the creation of slag, whilst removing contact with air to dramatically reduce the amount of contamination.

Ron Sewell, Chairman for HFT® said: “Available up to 600 amps, our Weld Backing Tape® has no true melting point so it works satisfactorily with TIG or MIG welding (GTAW or GMAW) where temperatures can reach up to 6,000ºC. This overcomes the concerns associated with ceramic fibre versions that have a melting point of 1,800ºC.”

Weld Backing Tape® is a material used for manual and automatic welding. It can help achieve higher welding speeds and dramatically reduce the amount of post weld cleaning required.

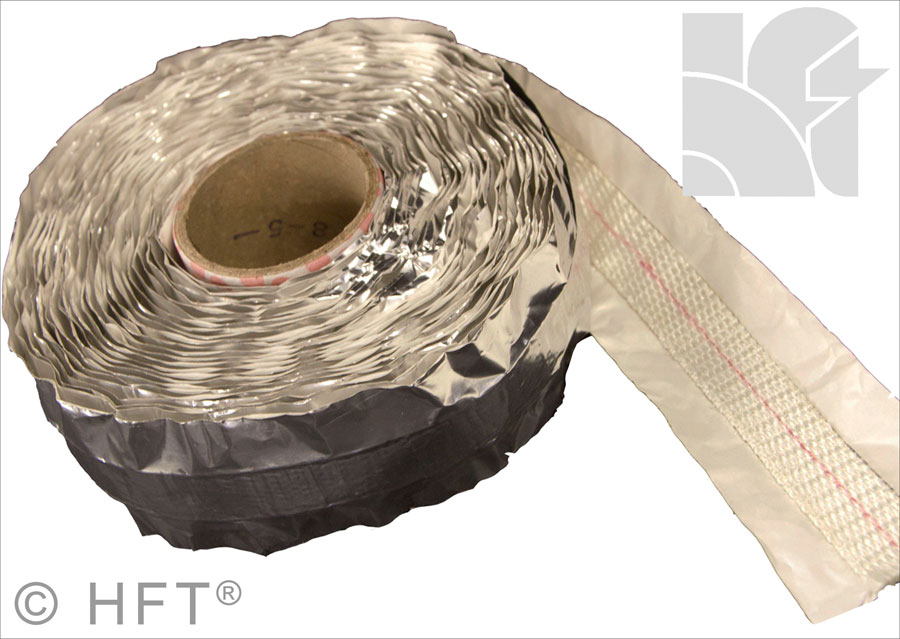

Each tape consists of a 3" (75mm) wide aluminium adhesive tape, in the centre of which is a 1" (25mm) wide band of woven glass fibre. The glass fibre matting has differing thicknesses to match the welding current in use.

Once the tape is positioned with the glass fibre matting under the centre of the weld joint, the welders can start their arc. The welding torch argon flow has plenty of space to move between the pores of the matting, which allows the welding arc to stabilise and start forming the weld root.

Huntingdon Fusion Techniques HFT® have a Worldwide Exclusive Distributor Network.

|

|

This Press Release is Succesfully Published in Worldwide Magazines, by clicking the logo you can read the article:

|

Read the published article directly in the magazine OilVoice |

|

Read the published article directly in the magazine World Industrial Reporter |

|

Read the published article directly in the magazine The Fabricator - The Welder |

You are not allowed to use or copy any of this material or content without the written permission of Huntingdon Fusion Techniques HFT®, copyright protected. All rights belong to Huntingdon Fusion Techniques HFT® exclusively. Not for any reproduction without consent.

|