Pipe Purging: Some pipe welding companies buy in sheets of thick foam and the dams then have to be hand made. During welding, the foam heats up and release fumes that are not healthy for a high purity weld or the welder.

Often, welders burn their hands whilst hurriedly removing a foam dam, which might have caught fire during welding. Masking tape used in their place can often start peeling off whilst the welder is oblivious.

Foam is highly porous and will be full of voids containing air, water vapour and maybe even hydrocarbons that will outgas as the dams become warm from the welding process.

Here at Huntingdon Fusion Techniques HFT®, we listen to our customers, designing and developing new innovative products to save welders time and money.

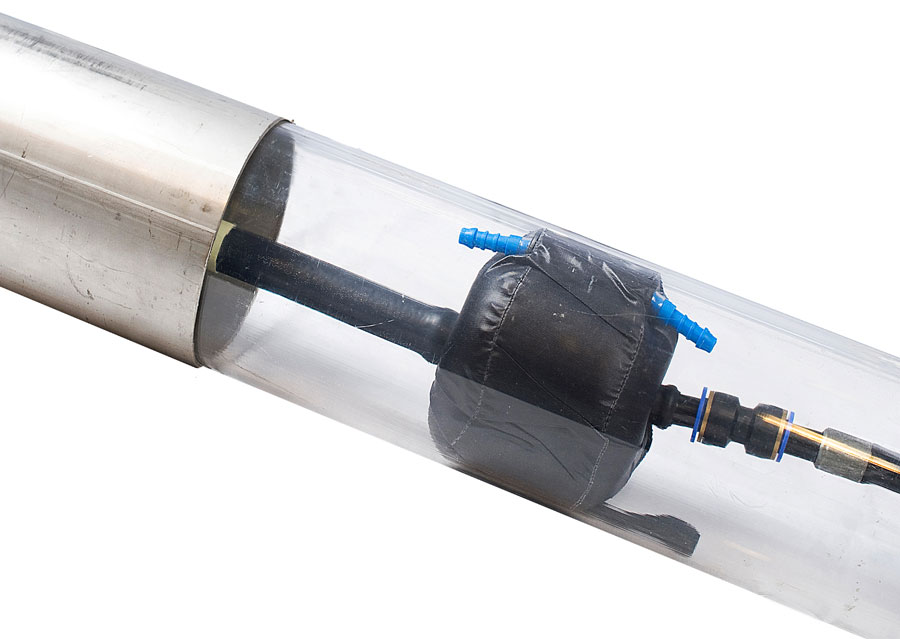

Our PurgElite® Inflatable Tube and Pipe Purging Systems are available in sizes 25 mm (1”), up to 610 mm (24”).

Key features of PurgElite® include: Other key features of this new range include:

Quotes from our Users:

“A friend called me up and needed 4-10” PurgElite® Inflatable Tube and Pipe Weld Purging Systems. He will be welding up stainless steel process piping in a local cheese factory and the PurgElite® System will save him a lot of time and argon. It is nice to invest in products that will but profit back in your pocket.”

“Near to completing 6" and 4" stainless steel pipe work at British Sugar, we used the PurgElite from Huntingdon Fusion Techniques, which was a great success saving us both time and gas. The 40" purge bags we purchased some 2 years ago have been worth their weight in gold to us in the construction phases of the large project we are coming to a close with. The 40" was always going to be problematic but the system we had worked perfectly.”