Earlier in the year, The Health and Safety Executive issued a safety alert as a result of new scientific evidence, which suggests that exposure to welding fume, including mild steel welding fume, can cause lung cancer.

Bulletin N. STSU1 – 2019

“All businesses undertaking welding activities should ensure effective engineering controls are provided and correctly used to control fume arising from those welding activities."

Eliminate Thoria:

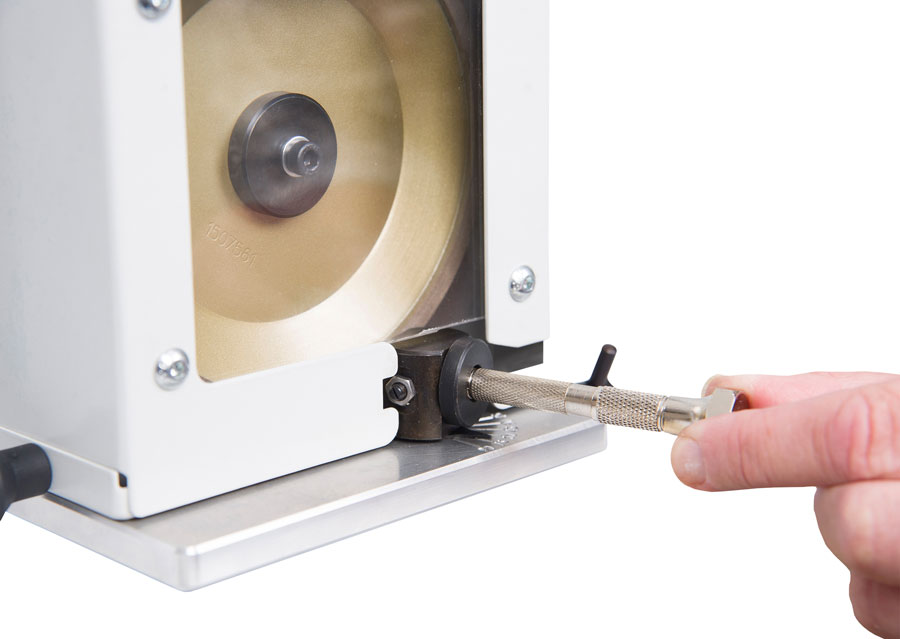

Thoriated Tungsten Electrodes contain thoria, a radiotoxic oxide that can also be dangerous to heath. During the grinding of the electrode there is a generation of radiotoxic dust, with the risk of this being inhaled by the welder.

Welders today continue to use thoriated Tungsten Electrodes. Thoria is cheaper than alternative oxides in lowering the work function of pure tungsten and this became the industry standard.

A Safe Tungsten Electrode:

HFT® identified the hazards associated with thoriated tungstens in the 1970s when the UK Health and Safety Directive first pointed out the risks associated with them.

We set out to produce a tungsten electrode that would be free of the radiotoxic thoria. Using research, we were able to produce a tungsten electrode that gave 10 times more arc strikes than thoriated tungsten electrodes under the same conditions and was able to perform well at low, medium and high current levels on DC welding as well as being able to work well with AC welders for materials such as aluminium.

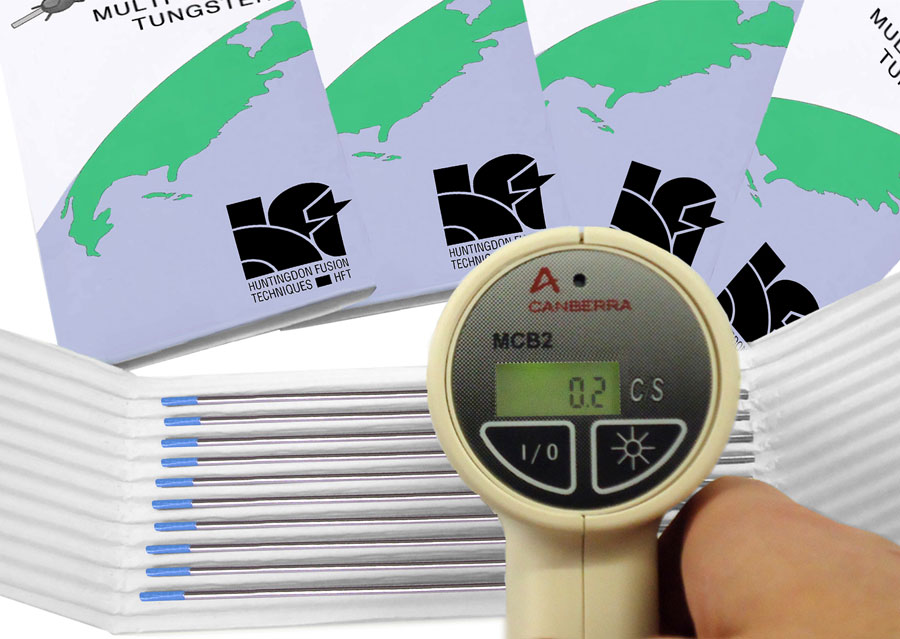

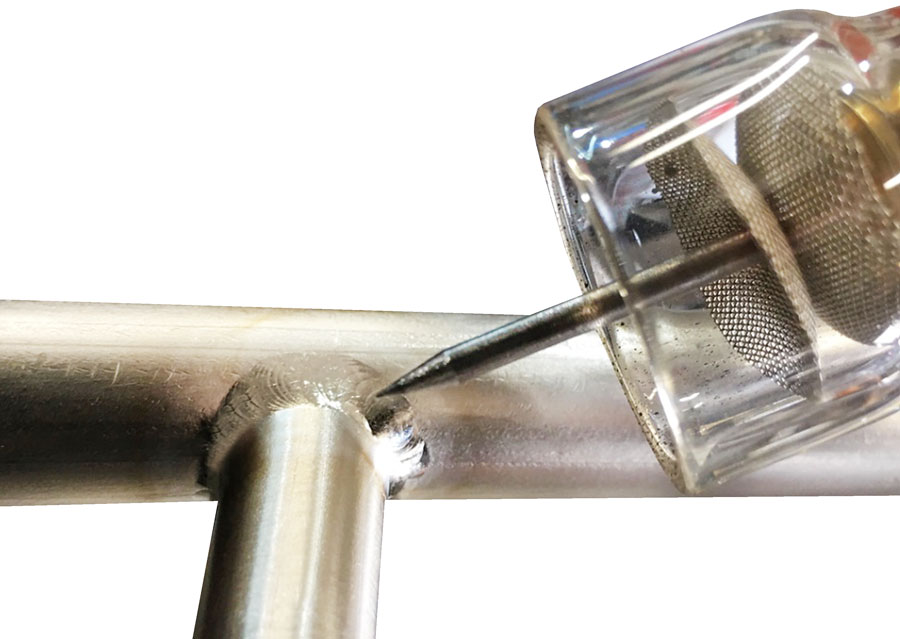

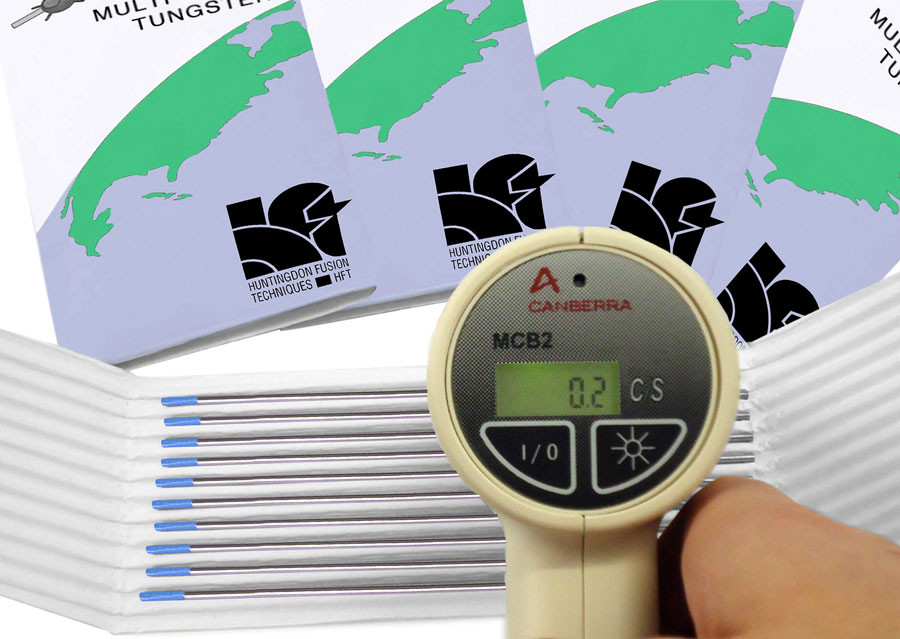

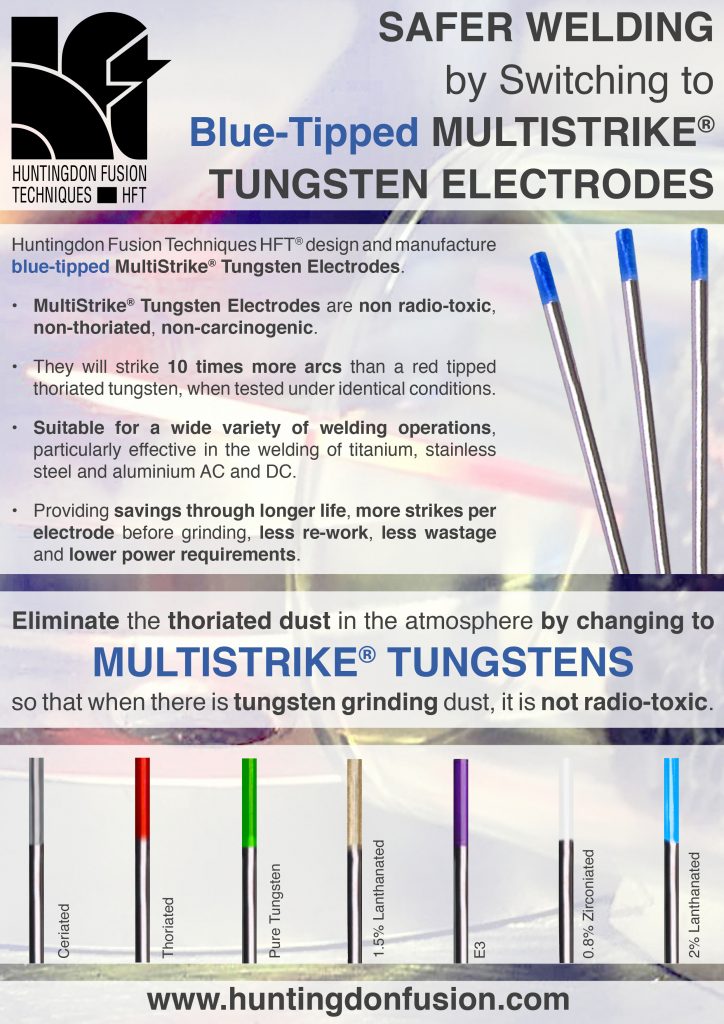

Blue Tipped MultiStrike® Tungsten Electrodes have been specifically designed to address the growing concerns about the radiotoxic thoria that is present in standard red tipped tungsten electrodes, MultiStrike® Tungsten Electrodes are non-radiotoxic, non-thoriated and non-carcinogenic.

Each packet of MultiStrike® Tungsten Electrodes carries a total traceability identification and these are suitable for a wide variety of welding operations, particularly effective in the welding of titanium, stainless steel and aluminium.

MultiStrike® Tungsten Electrodes provide savings through longer life, more strikes per electrode before grinding, less re-work, less wastage and lower power requirements.

Read more about the Techweld® MultiStrike® Tungsten Electrodes on the HFT® website: MultiStrike® Tungsten Electrodes.