Welding Chambers make it possible to weld stainless steels, titanium and other reactive alloys effectively without oxidation and discolouration.

The ever-increasing demand in the Aerospace, Medical Scientific and Nuclear Industries for high-quality welded components has forced new technology for reactive metals such as titanium to be welded in a complete inert gas coverage.

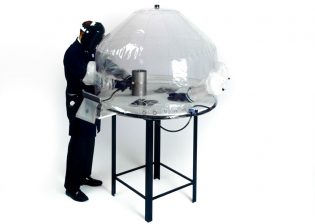

Flexible Welding Chambers (Enclosures) are a cost-effective way for welders to maintain an atmosphere that’s entirely inert. Metal enclosures have been the most common choice for fabricators, even though such equipment has always been very expensive to produce and operate.

Titanium

Welding titanium demands more care than usual. Titanium is highly reactive and will form compounds with undesirable elements. If the metal is heated in air, the surface of the part will gain carbides, nitrides and oxides that may reduce the weld’s corrosion resistance properties and toughness, as well as that of the heated zone.

The techniques and equipment used to weld titanium are similar to those required for other high-performance materials. Titanium demands greater attention to cleanliness and to the use of auxiliary inert gas shielding than those materials.

Huntingdon Fusion Techniques HFT®’s version of the Welding Chambers are manufactured from UV resistant PVC and have proved to be extremely successful for welding with oxygen levels down to 10 parts per million. The Flexible Welding Enclosures® are manufactured as standard with two sets of glove ports but extra sets can be specified. The upper half of the enclosure is optically clear and provides excellent welding vision. An entry lock is fitted for small parts to be taken in and out without loss of purge quality. An exhaust valve allows continuous purging so that impurities can be expelled during welding.

Stainless Steels

Although welding stainless steel components inside Flexible Welding Enclosures® is not essential, the cost and time savings might be considered a justifiable reason to begin welding in totally inert atmospheres rather than pouring away expensive argon gas by welding in ambient conditions and trying to shield from the front and purging the backside simultaneously.

Having examined the staggering cost differences of argon from enclosure welding to ambient welding, by adding the savings of time in cleaning and/or pickling, there is another significant sum of money to be saved. The purchase and disposal costs of pickling fluids needs to be taken into consideration as well as the costs of abrasives and polishing materials.

A Return on Investment (ROI) chart is available showing the extent of these enormous savings.