QuickPurge Pipe and Pipeline Weld Purging Systems are manufactured up to 88” Diameter (2’235 mm).

Filling and purging large pipe diameters ready for welding with an inert gas is very costly. Not only is a lot of time spent waiting, but also a large volume of gas is required.

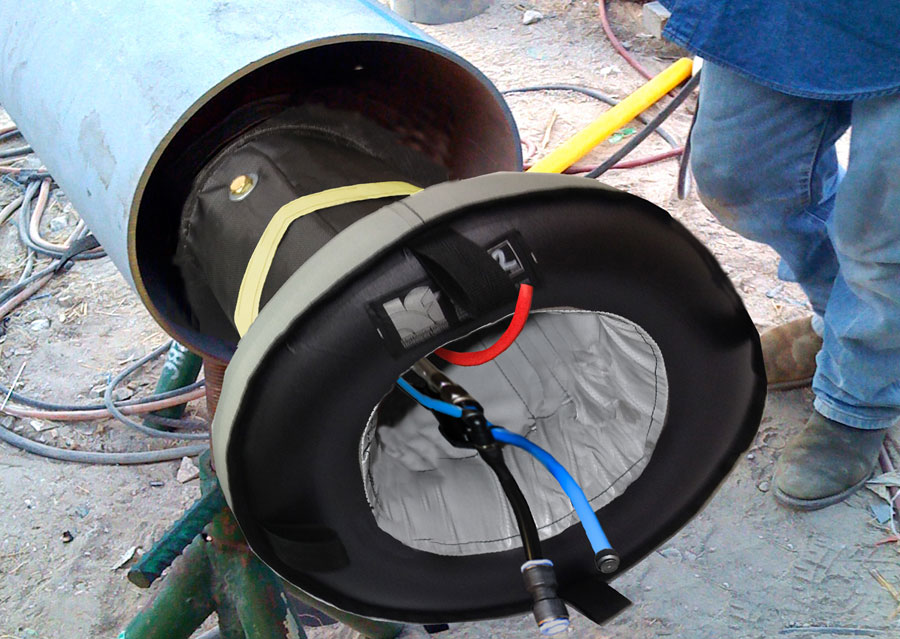

Weld Purging Experts Huntingdon Fusion Techniques HFT® design and manufacture QuickPurge ®, Pipe and Pipeline Weld Purging Systems available in sizes 6 to 88” (150 to 2,235 mm). These unique Pipe Purging Systems inflate inside pipes, restricting the weld purging zone, meaning far less gas is required to purge the section of pipe and much shorter waiting times.

The return on investment (ROI) for these devices is lower than one single use on a weld.

The material from which QuickPurge ® systems is manufactured, has a high temperature resistance and a low outgassing rate to help speed up the weld purge.

There are no complicated adjustable valves with Quick Purge systems, as they have a newly developed method that allows inflation of the dams and purging of the system at the optimum flow rate to ensure minimum usage of expensive inert gas without any adjustments.

The HFT developed and registered devices called IntaCal® and PurgeGate® are coupled with the QuickPurge® Systems and are guaranteed not to over inflate and burst due to over pressurisation, which would otherwise destroy the systems and risk the loss of the weld.

RootGlo®, a luminescent glow band in the centre of the QuickPurge system to help the welder position each system within the dark cavity of the pipe.

Visual identification of positioning can be made easily through the root gap of the pipe joint with RootGlo®.

This is truly a magnificent state of the art 21st century ‘plug and play’ pipe weld purging system that is a must for all industries welding stainless, duplex and chrome steels, titanium, zirconium or nickel alloys.

For Chrome steels and high pressure stainless steel pipe joints that may have to be pre- and/or post heat treated, the manufacturer, Huntingdon Fusion Techniques HFT® manufactures a system called “HotPurge®” using high temperature resistant materials to avoid any damage and to enable use of the system many times over.

Make money while you weld…..!

Money and time savings using these HotPurge ® and QuickPurge ® Systems will have paid for the costs of the units in the first weld. After that the savings are very significant.