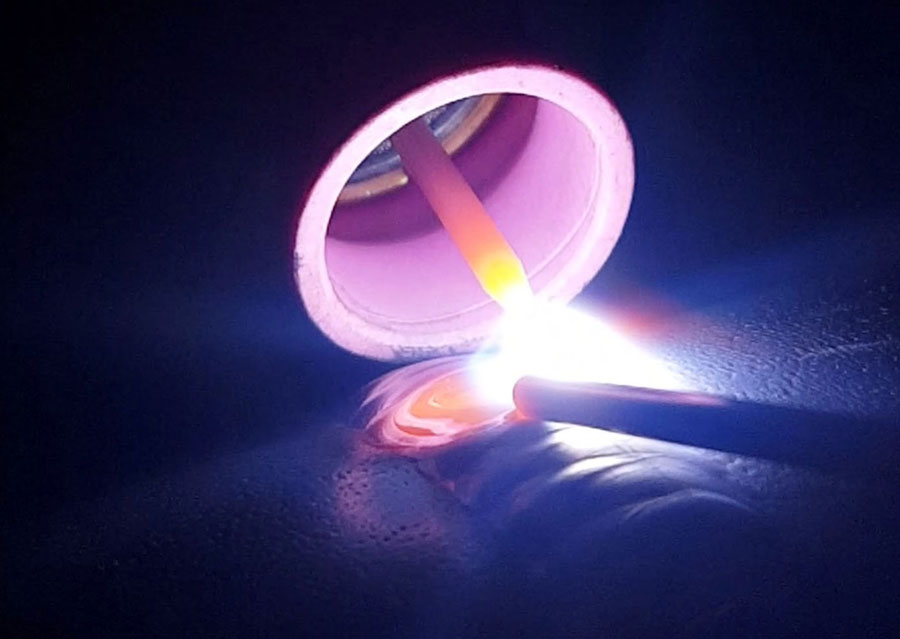

Tungsten is chosen for producing the welding arc because of its hardness and high-temperature resistance to carry the welding current to the arc. Tungsten has the highest melting point of any metal, 3,410 degrees Celsius (6,170ºF).

The role played by the electrode is therefore crucial. It must have a high melting point and it must be non-consumable. Tungsten quickly established itself as the most suitable material for arc welding.

However, pure tungsten alone requires a very heavy voltage to strike an arc that for most applications would make the welding process less economical so specialists discovered that the addition certain rare earth elements would lower the striking voltage, thus making the welding power supplies affordable

Due to the costs of rare earth elements, the least expensive thoria was the one originally chosen and which today is still the most widely used with its familiar red tip. However, thorium is radiotoxic so health and safety specialists need to be aware of guidelines for storage of Electrodes and disposal of the dust created by the constant regrinding process.

One way around these difficulties and health concerns, is to use the MultiStrike® Blue Tipped Tungsten Electrodes that uses non-radiotoxic elements.

What can MultiStrike Tungsten Electrodes offer?

Blue Tipped MultiStrike® Tungsten Electrodes have been specifically designed by Huntingdon Fusion Techniques HFT® to address the growing concerns about the radio-toxic thoria that is present in standard red tipped tungsten electrodes, MultiStrike® Tungsten Electrodes are non-radiotoxic, non-thoriated and non-carcinogenic.

They maintain a high performance and will strike 10 times more arcs than red tipped thoriated tungsten, when tested under identical conditions.

Each packet of MultiStrike® Tungsten Electrodes carries a total traceability identification and are suitable for a wide variety of welding operations, particularly effective in the welding of titanium, stainless steel and aluminium AC and DC.

MultiStrike® Tungsten Electrodes provide savings through longer life, more strikes per electrode before grinding, less re-work, less wastage and lower power requirements.

Eliminate the thoriated dust in the atmosphere by changing to MultiStrike® Tungstens so that when there is tungsten grinding dust, it is not radiotoxic.

The following video link shows an instrument measuring the radiotoxic levels of red tipped tungstens verses the zero level that MultiStrike® Tungsten Electrodes have.